Exploring the Limitations of Copper-Clad Aluminum Wire in High-Frequency Applications

2023-09-13

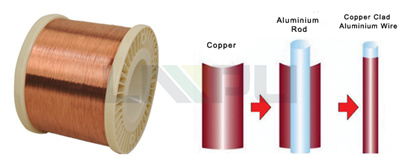

In the world of electrical engineering, selecting the right materials for specific applications is crucial for ensuring optimal performance and safety. Copper-clad aluminum (CCA) wire has gained popularity in recent years due to its cost-effectiveness and lightweight properties. However, it's important to understand that CCA wire may not be suitable for all applications, especially in high-frequency scenarios. In this blog post, we'll delve into the limitations of CCA wire in high-frequency applications and explore potential alternatives.

Skin Effect

One of the primary limitations of CCA wire in high-frequency applications is the phenomenon known as the skin effect. At higher frequencies, electrical currents tend to flow primarily on the outer surface of the conductor, leading to increased resistance. Since aluminum has a lower conductivity compared to copper, the skin effect becomes more pronounced in CCA wire, resulting in higher losses and reduced efficiency.

Increased Signal Attenuation

Signal attenuation is another critical factor to consider when using CCA wire in high-frequency applications. Due to the skin effect and the inherent differences in conductivity between copper and aluminum, CCA wire experiences higher signal loss as frequencies increase. This can lead to weakened signals, reduced transmission distances, and compromised overall performance in high-frequency systems.

Limited Thermal Conductivity

In high-frequency applications, heat dissipation is a crucial consideration. Copper boasts superior thermal conductivity compared to aluminum, meaning it can effectively dissipate heat generated during operation. CCA wire, with its aluminum core, struggles to manage heat in high-frequency scenarios, potentially leading to overheating and reduced reliability.

Potential for Galvanic Corrosion

Galvanic corrosion is a concern when using CCA wire in certain environments. This occurs when aluminum comes into contact with other metals, particularly in the presence of moisture or corrosive substances. The dissimilar metals create an electrochemical reaction that can lead to corrosion, potentially compromising the integrity and performance of the wire.

Mechanical Strength and Durability

Copper-clad aluminum wire typically has a softer, less robust core compared to solid copper wire. This can lead to challenges in terms of mechanical strength and durability, especially in applications where the wire is subject to bending, twisting, or other forms of mechanical stress. Over time, CCA wire may be more susceptible to physical damage and wear compared to solid copper alternatives.

Potential Alternatives

When high-frequency applications demand reliable performance, considering alternative materials is crucial. Some potential alternatives to CCA wire in high-frequency scenarios include:

Solid Copper Wire: Solid copper wire offers superior conductivity, reduced skin effect, and higher thermal conductivity compared to CCA wire. While it may be slightly more expensive, it provides enhanced performance and durability in high-frequency applications.

Silver-Plated Copper Wire: Silver-plated copper wire combines the excellent conductivity of copper with the enhanced surface properties of silver. This combination can help mitigate skin effect and improve overall performance in high-frequency systems.

Conclusion

While copper-clad aluminum wire has its advantages, such as cost-effectiveness and lightweight properties, it's important to acknowledge its limitations in high-frequency applications. The skin effect, signal attenuation, thermal conductivity, potential for galvanic corrosion, and mechanical strength are all factors that need to be considered. When high-frequency performance is paramount, exploring alternative materials like solid copper or silver-plated copper wire may be a more prudent choice. Ultimately, selecting the right wire for a specific application requires a thorough understanding of the operational requirements and potential trade-offs involved.