Self-Bonding EIW Copper Wire: Revolutionizing Electrical Connections

2023-08-07

In the world of electrical engineering, the constant pursuit of innovation and efficiency drives the development of groundbreaking technologies. Among these advancements, self-bonding enameled insulated wire (EIW) has emerged as a game-changer, offering significant benefits over traditional wiring solutions. In this blog, we'll explore the fascinating world of self-bonding EIW copper wire and the remarkable impact it has on electrical connections.

Understanding Enameled Insulated Wire (EIW)

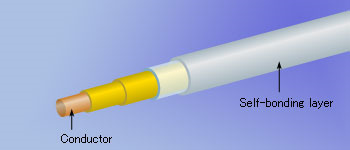

Enameled insulated wire, also known as magnet wire, is a type of copper wire coated with a thin layer of enamel insulation. This insulation is crucial because it prevents the copper conductors from coming into direct contact with one another, reducing the risk of short circuits and improving overall safety. Traditional EIW has been widely used in various applications such as motors, transformers, solenoids, and inductors.

The Need for Self-Bonding EIW Copper Wire

While traditional EIW served its purpose well, it was not without its challenges. One significant obstacle was the necessity of removing the enamel insulation before making electrical connections. Stripping the enamel was a delicate and time-consuming process, often involving the use of hazardous chemicals. This not only added to production costs but also introduced potential quality issues and safety concerns.

Self-bonding EIW was developed to address these limitations and provide a more efficient and reliable solution for electrical connections.

How Self-Bonding EIW Copper Wire Works

Self-bonding EIW is coated with a unique type of enamel that exhibits a remarkable property: when heated, the enamel softens and adheres to itself, forming a strong and durable bond. This eliminates the need for stripping the insulation, as the wire can be easily joined by applying heat to initiate the bonding process.

The bonding mechanism involves a controlled temperature application, typically achieved through soldering irons, hot air guns, or other specialized equipment. Once the wire is heated to the appropriate temperature, the enamel fuses together, creating a seamless electrical connection.

Advantages of Self-Bonding EIW Copper Wire

Time and Cost Efficiency: The elimination of the enamel stripping process saves significant time and reduces production costs. This efficiency makes self-bonding EIW an attractive option for high-volume manufacturing.

Improved Reliability: The self-bonding process creates a robust and consistent connection, minimizing the risk of loose joints or poor conductivity.

Enhanced Safety: As there is no need for chemical stripping, the potential hazards associated with traditional enamel removal are eliminated. This contributes to a safer working environment for operators and reduces the risk of product defects due to improper handling.

Space-Saving Design: Self-bonding EIW allows for more compact and efficient designs, as the absence of additional connection materials reduces the overall footprint.

Versatility: Self-bonding EIW can be applied in various industries and applications where traditional EIW is used, such as motors, transformers, and solenoids.

Challenges and Considerations

While self-bonding EIW brings numerous advantages, it's essential to consider certain factors during its implementation:

Temperature Sensitivity: The bonding process relies on controlled heat, so it's crucial to avoid overheating, which could damage the enamel or affect the electrical properties of the wire.

Skill and Equipment Requirements: Operators must be trained in the proper bonding techniques, and specialized equipment may be necessary for consistent and reliable connections.

Compatibility: Self-bonding EIW may not be suitable for all applications, so it's essential to assess its compatibility with specific project requirements.

Conclusion

Self-bonding enameled insulated copper wire represents a significant leap forward in electrical connection technology. Its ability to form strong, reliable, and cost-effective connections without the need for enamel stripping makes it an appealing choice for various industries. As this technology continues to evolve, we can expect to see even greater advancements in electrical engineering, ushering in a new era of efficiency and safety for countless applications.