The Electrifying Wonders of Enameled Wires in Dry Transformers

2023-09-22

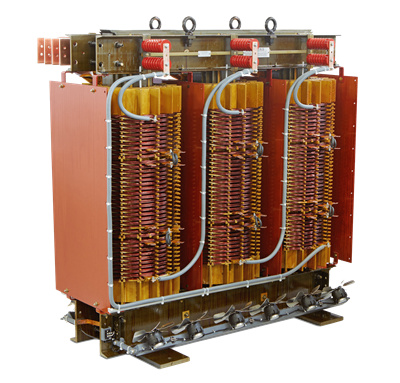

In the world of electrical engineering, transformers are essential devices that play a pivotal role in transmitting and distributing electrical energy. Among the various types of transformers, dry transformers have gained significant popularity due to their safety, reliability, and efficiency. At the heart of these transformers lies a lesser-known but indispensable component: enameled wires. In this blog, we will delve into the world of enameled wires and explore their critical role in dry transformers.

Enameled wires, also known as magnet wires or winding wires, are insulated copper or aluminum wires coated with a thin layer of enamel insulation. This enamel coating is typically made of polymers or resins and provides electrical insulation while allowing for efficient electrical conduction within the wire. Enameled wires are widely used in various electrical applications, including motors, generators, and, of course, dry transformers.

The Significance of Enameled Wires in Dry Transformers

Electrical Insulation: One of the primary functions of enameled wires in dry transformers is to provide electrical insulation. Transformers operate at high voltages, and preventing electrical short circuits is crucial for their safe and efficient functioning. The enamel coating on the wires ensures that the current flows along the intended path, minimizing the risk of short circuits and damage to the transformer.

High Temperature Resistance: Dry transformers are designed to operate in a wide range of environmental conditions. Enameled wires are chosen for their ability to withstand high temperatures without compromising their insulating properties. This feature is vital because transformers generate heat during operation, and the wires must endure these elevated temperatures without degrading.

Space Efficiency: Dry transformers are often preferred in compact installations or areas with space constraints. Enameled wires are thin and allow for more compact winding configurations, maximizing the space utilization within the transformer. This makes them ideal for transformers installed in urban areas or buildings with limited space.

Durability: Enameled wires are known for their durability and resistance to abrasion and mechanical stress. This is essential because the winding of transformers is subject to both mechanical and electromagnetic forces. The robust insulation provided by enameled wires ensures that the transformer can withstand these stresses over its operational life.

Improved Efficiency: The choice of enameled wires can significantly impact the overall efficiency of a dry transformer. The enamel insulation reduces energy losses due to electrical resistance, enhancing the transformer's efficiency and reducing energy consumption.

Types of Enameled Wires

Enameled wires come in various types and classifications to suit different transformer applications:

Thermal Class: Enameled wires are classified based on their ability to withstand different temperature levels. Classes such as 130°C, 155°C, and 180°C are common choices for dry transformers, with higher classes indicating greater temperature resistance.

Size and Gauge: The diameter of enameled wires, often referred to as their gauge, can vary to meet specific design requirements. Smaller gauges offer greater current-carrying capacity but may take up more space, while larger gauges are more space-efficient but have lower current-carrying capacity.

Insulation Material: The choice of enamel insulation material can affect the wire's resistance to chemicals, moisture, and temperature extremes. Polyurethane, polyester, and polyimide are some common insulation materials.

Conclusion

Enameled wires are the unsung heroes of dry transformers, silently enabling these vital electrical devices to function efficiently and safely. Their unique combination of electrical insulation, temperature resistance, space efficiency, and durability make them indispensable components in the world of electrical engineering. As technology continues to evolve, enameled wires will likely play an even more critical role in the development of advanced and high-performance dry transformers, helping us meet the growing demand for reliable electrical power distribution.