Home » enameled aluminum wire » Enameled Aluminum Self Bonding Wire In Hot Air Or Alcohol Type

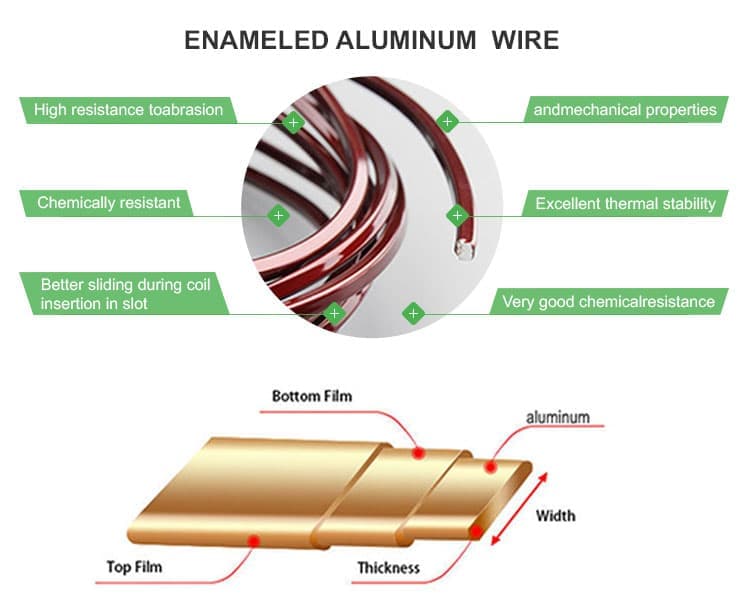

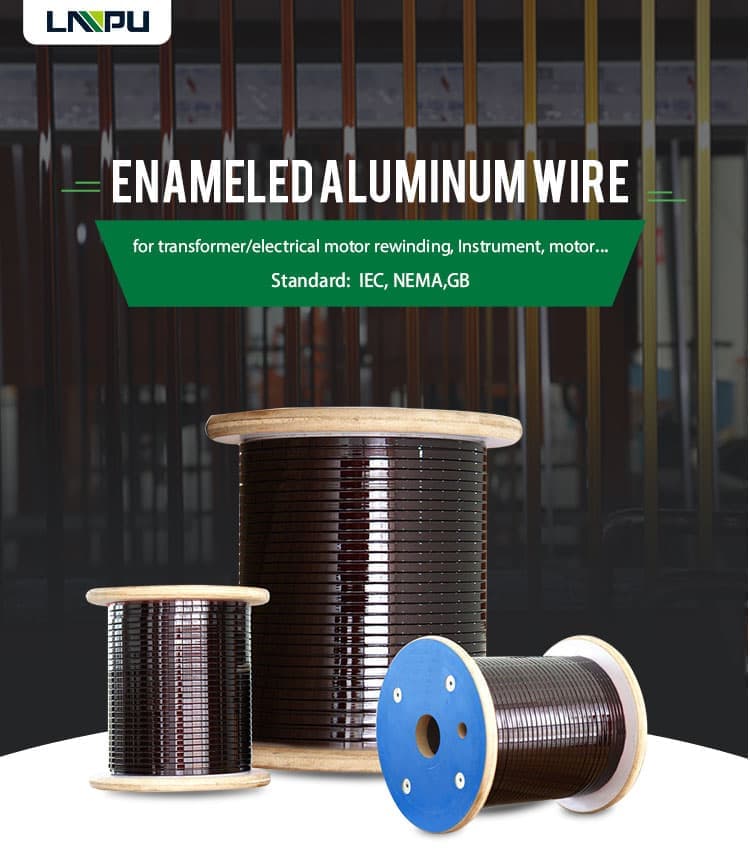

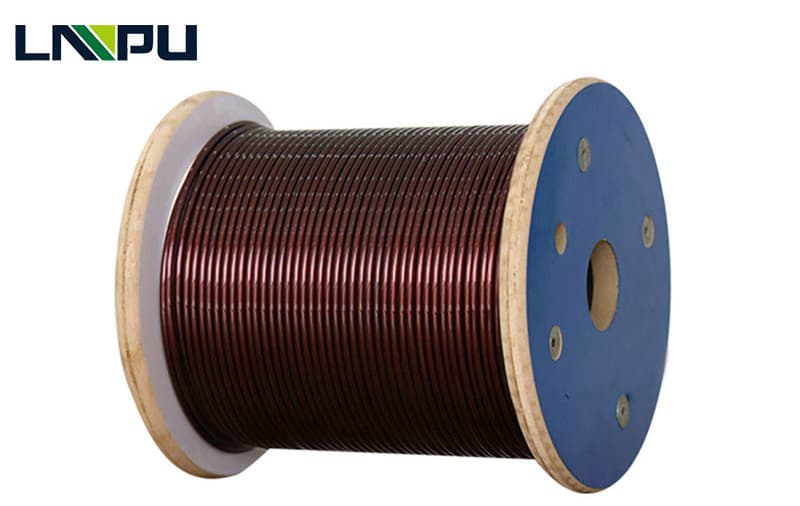

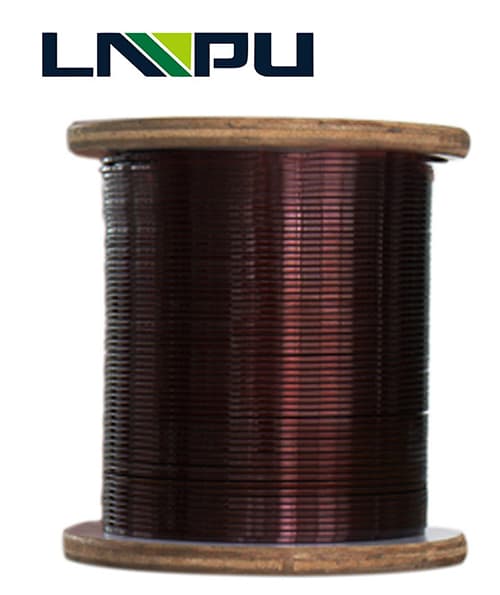

Enameled Aluminum Self Bonding Wire In Hot Air Or Alcohol Type

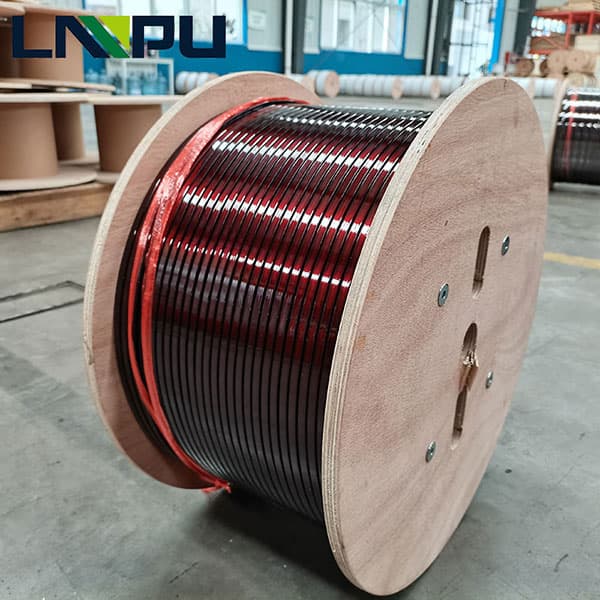

Enameled Aluminum Self Bonding Wire In Hot Air Or Alcohol Type: When the alcohol is added to the product, the wound coils are naturally bonded together and directly formed. Hot air self-adhesive is achieved by blowing hot air on the product coil during the coil winding process to achieve the self-adhesive effect. The temperature of the hot air varies according to different paint film, winding speed, wire diameter and other factors.

Contact US

Get Price

Share:

Content

Hot melt self-adhesive is a way to achieve self-adhesive effect by energizing the coil during the winding process. The electrified voltage gradually increases the temperature from the low volt voltage according to the size of the wire, until the product forms a self-adhesive method.

Inquiry

More enameled aluminum wire