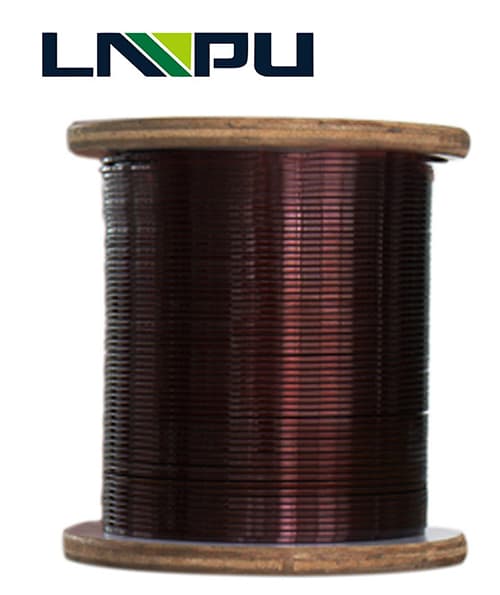

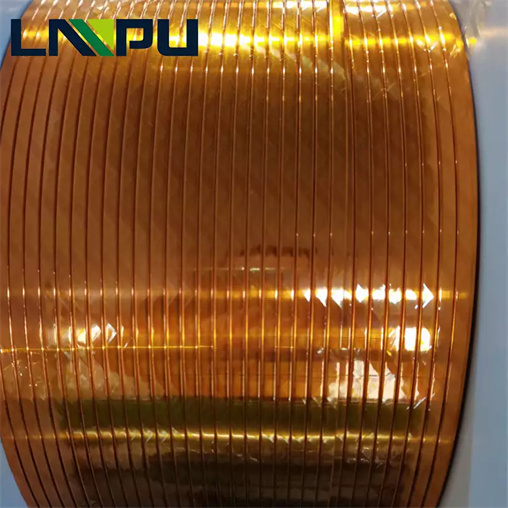

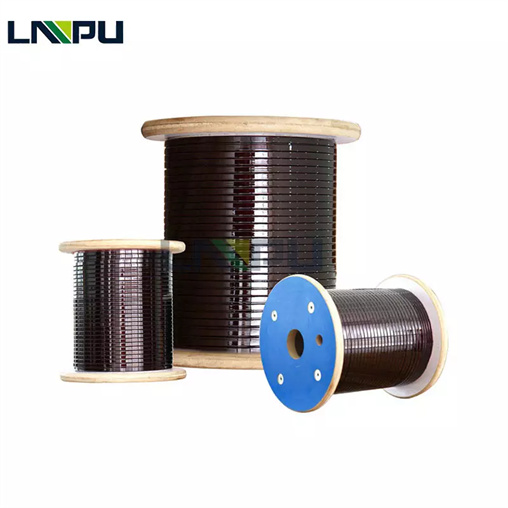

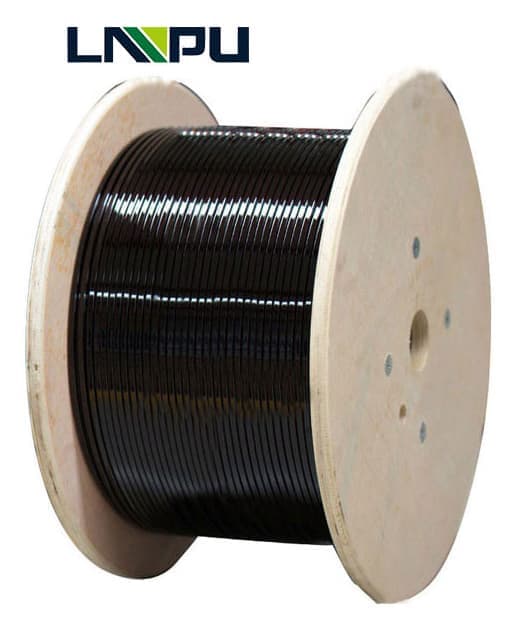

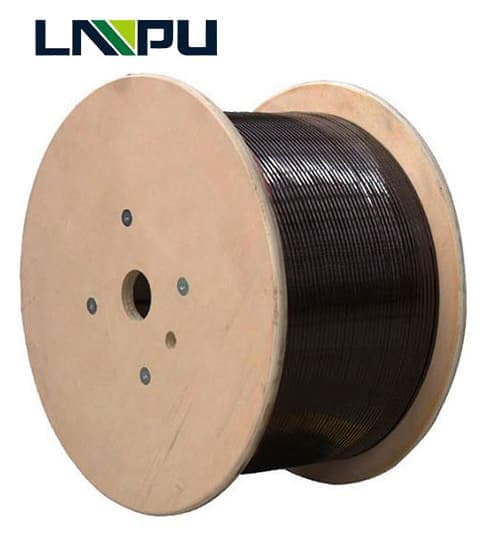

34 awg High Temperature Colored Enameled Aluminum Magnet Wire

34 awg High Temperature Colored Enameled Aluminum Magnet Wire is a main type of winding wire. It consists of a conductor and an insulating layer. After the bare wire is softened by annealing, it is painted and baked many times. It is the main raw material for products such as motors, electrical appliances and household appliances. Especially in recent years, the electric power industry has achieved sustained and rapid growth. The rapid development of household appliances has brought a broader field to the application of enameled wires.

Enameled wire specification table:

It is not easy to produce enameled wires that not only meet the standard requirements, but also meet customer requirements. It is affected by the quality of raw materials, process parameters, production equipment, environment and other factors. Therefore, the quality characteristics of various enameled wires are different, but they all have machinery. Performance, chemical performance, electrical performance, and thermal performance are four major properties. The following is the enameled wire specification table:

Domestic enameled wire specification table:

=2.5A/mm2.j=3A/mm2 refers to the allowable safe current, [unit mm2).

9w/220v=0.041A=41mA,

0.25mm enameled wire cross-sectional area=0.25*0.25*3.14=0.19625

0.1925mm2*3A=0.58875A=589MA