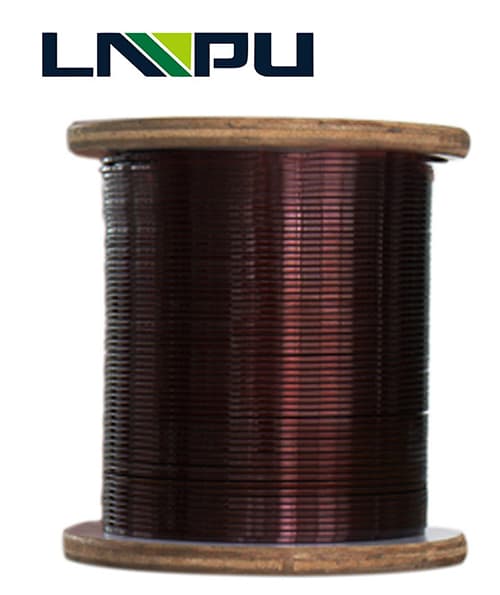

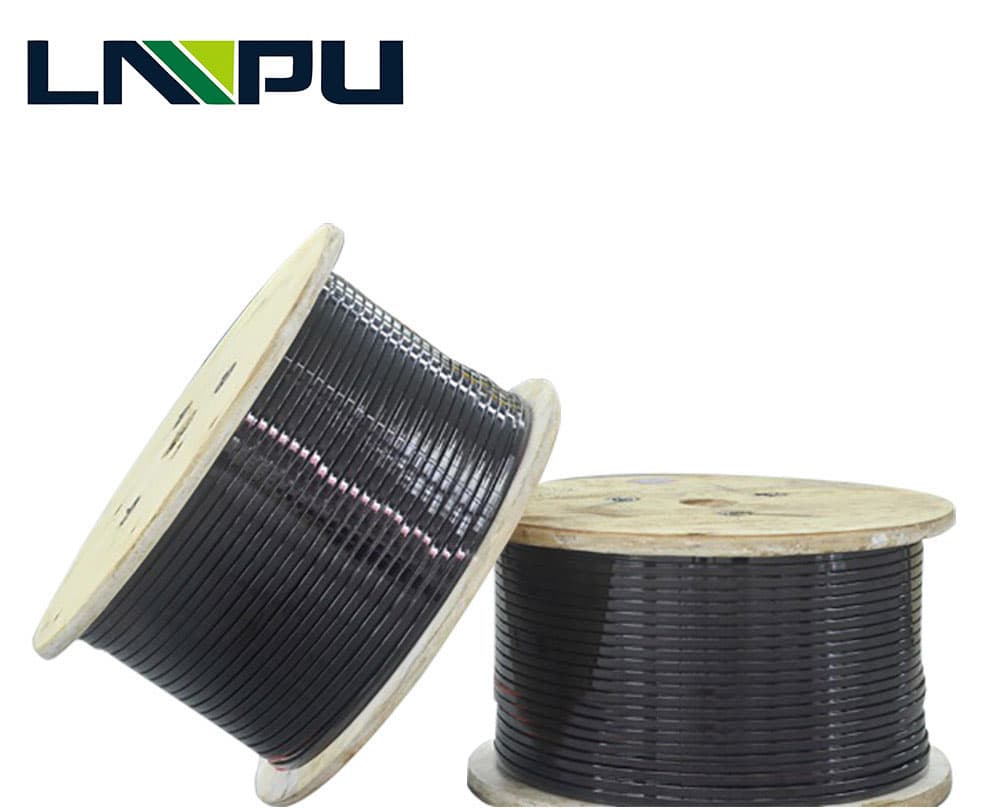

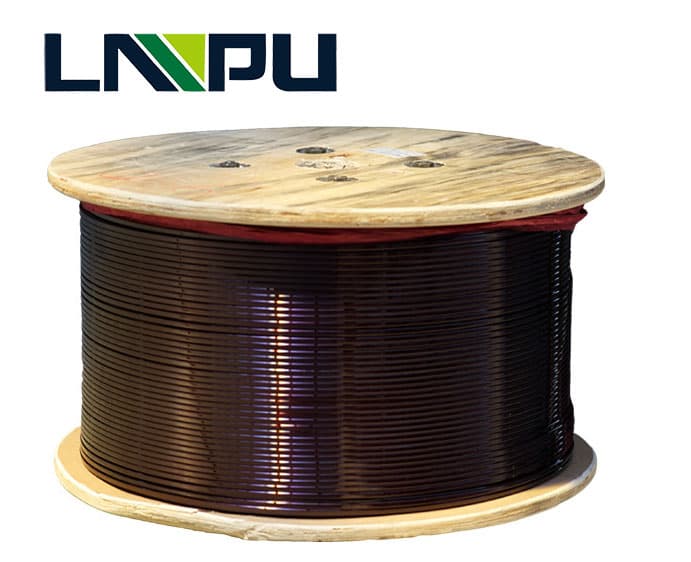

High Quality Thin Insulated Solderable Enameled Aluminum Wire

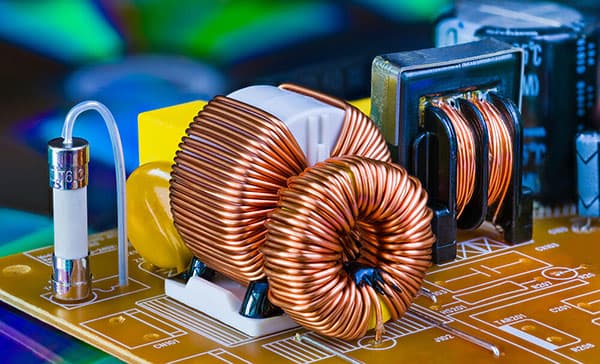

High Quality Thin Insulated Solderable Enameled Aluminum Wire is used for Ttansformers, motors, and generators are all machines based on coils, which are devices that use large coils to generate magnetic fields and currents.

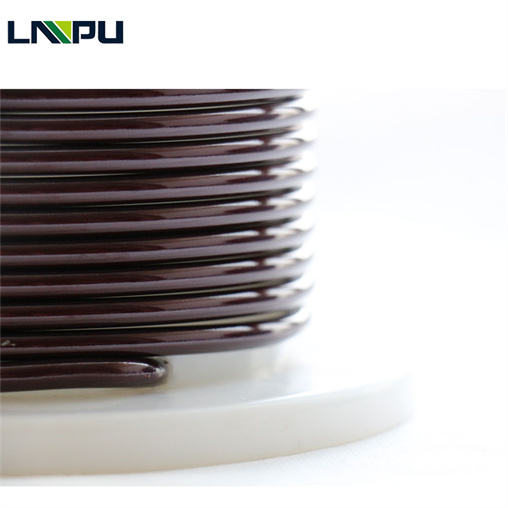

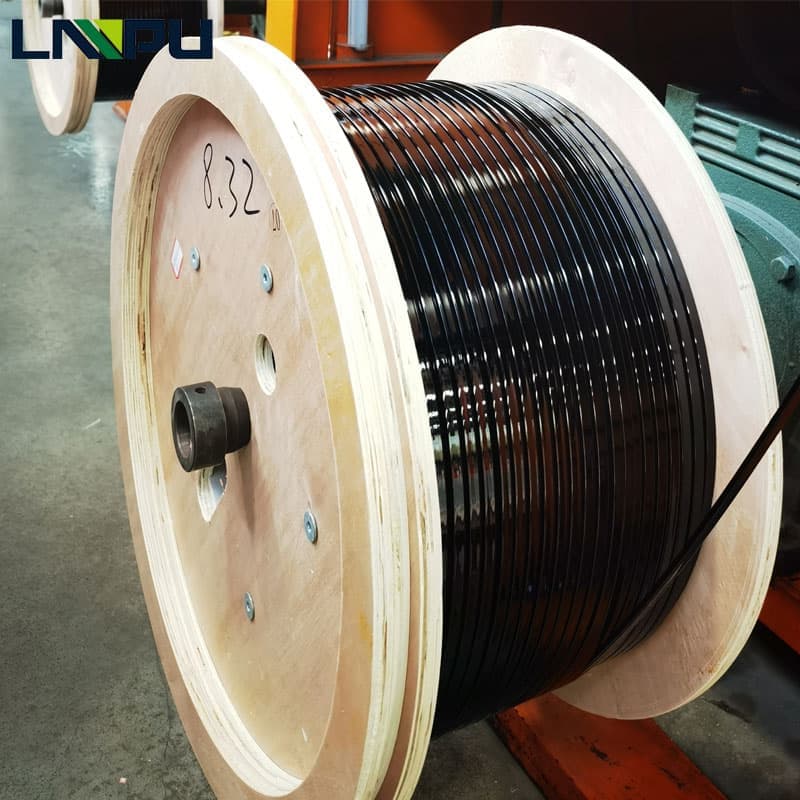

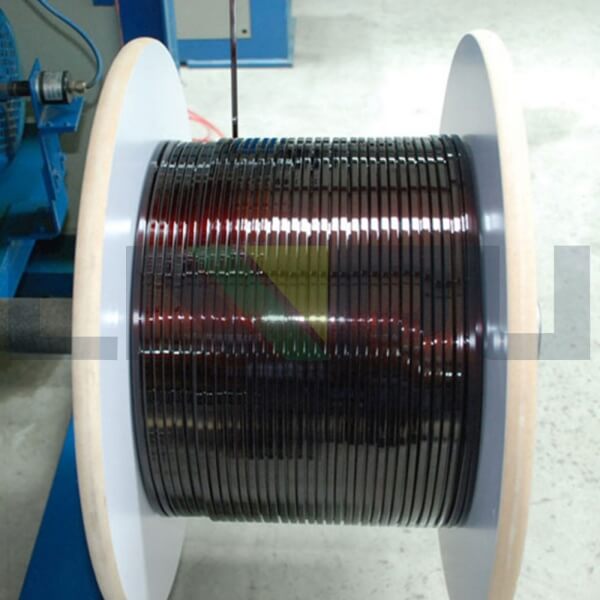

One of the main characteristics that make enameled aluminum wire suitable for a wide range of applications is the thin enameled insulation layer. Transformers, motors, and generators are all machines based on coils, which are devices that use large coils to generate magnetic fields and currents. The smaller these devices are, the stronger they are. Because enameled aluminum magnet wire and enameled copper magnet wire are insulated by a thin layer of enamel, instead of other types of thicker insulators, such as paper, glass fiber, mica, etc. Since the enameled aluminum wire or enameled copper wire occupies a smaller space in the formation of the coil, the coil is more effective, more compact, and more efficient.