What is the first thing to make the enamel wire?

What is the first thing to make the enamel wire? And the manufacutring process of enameled wire is important, the extruding and baking. And the raw materials: copper conductor or aluminum conductor is enough for client’s requiremnets

1. Display

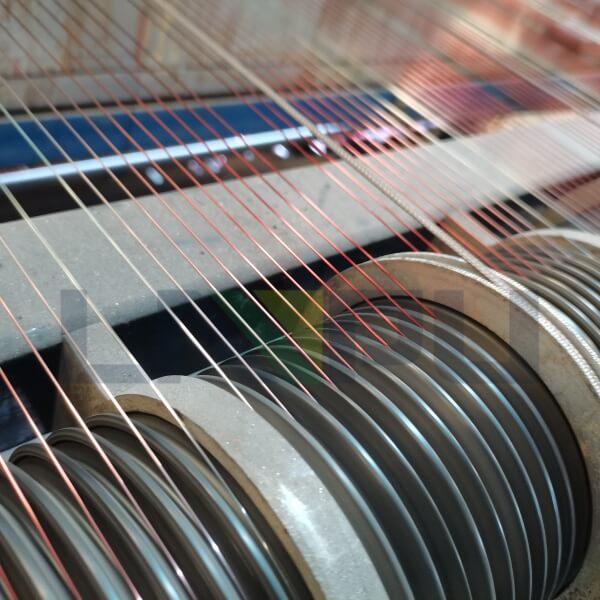

On a normal operation of the enameled wire, the operator’s energy and physical strength consumes most of the disposal portion, and the dispatching disc will make the operator pay a lot of labor, change The wire is easy to generate quality problems and operational failures. A effective method is a large-capacity placement. The key to the release is to control the tension. When the tension is large, not only the conductor is pulled, so that the surface of the wire is lifted, and the multi-performance of the enameled wire is also affected. From the appearance, the wire drawn wire is poorly linked. From performance, the enamel wire elongation, elasticity, flexibility, and thermal shock are affected. The tension tension is too small, and the wire is easy to jump to cause a parallel and the miles. The half-circle tension is mostly large, and the semi-circular tension is small, not only makes the wire loose, tie, and a section is pulled, but also causes a large beating of the inner wire of the oven, causing a pairing, tap wire failure. The tension is uniform, appropriate. It is helpful for installing the control wheel before the annealing furnace. The soft copper wire is about 15 kg / mm2 at room temperature, and the maximum non-extended tension at 400 ¡ã C is about 7kg / mm2; at 460 ¡ã C, the maximum non-extended tension is 4kg / mm2; the greatest in 500 ¡ã C The extension tension is 2 kg / mm2. During normal enameled wire coating, the tension of the lacquer wire should be significantly less than the non-extended tension, and the control is controlled around 50%, and the tension control is controlled around 20% of the non-extended tension.

Large-specific large-capacity spools generally use radial rotary discharged amplifiers; medium-specific wires generally adopt an output-oriented or brushed amplifier; micro-specific wires generally use brush or double cone sleeve Display.

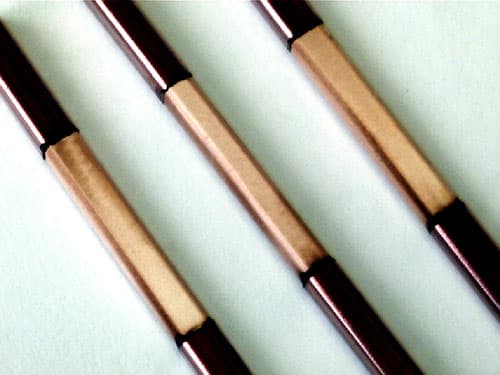

No matter which placement method is used, there is strict requirements for the structure and quality of the bare copper wire spool

The surface should be smooth to ensure the wire is not wounded

axis The R angle of 2-4 mm radius in both sides and side panels inside and outside the side plates to ensure equal balance during the release process

After the spool processing is completed, it must act, static balance test

brush The dispenser requires a diameter of the shaft: the side plate diameter is less than 1: 1.7; the output of the over-deck is less than 1: 1.9, otherwise the disconnection is displayed to the shaft.

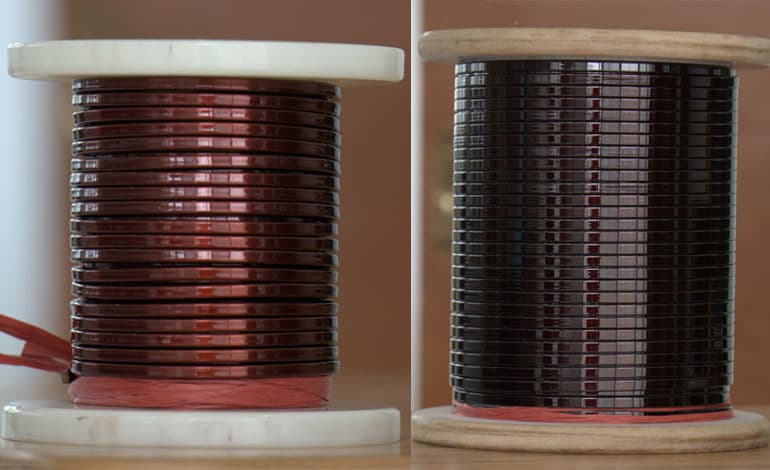

2. Annealing

The purpose of annealing is to cause the conductor to heat the molecule to rearrange the molecular lattice rearrangement due to the change in the wire due to the variation of the lattice during the mold tensile process. The softness of the process requires, while removing lubricants, oil, etc. in the surface of the conductor during the stretching process, so that the wires are easily painted to ensure the quality of the painted wire. Most importantly, it is to ensure that the enameled wire has a suitable softness and elongation during the use of the winding, while contributing to increase the conductivity.

The larger the conductor deformation, the lower the elongation, the higher the tensile strength.

The annealing of the copper wire, there are three ways to use: an annealing of a dish; a continuous annealing on the drawing machine; continuous annealing on the enameled machine. The first two ways cannot be fullRequirements for lacquered bags. The anneal annealing can only soften the copper wire, and the oil is not thorough, due to the soft wire after the annealing, the bend is increased. Continuous annealing on the brigade, although the softening and removal of the surface of the copper wire can be reached, but the soft copper wire after annealing has a lot of bending on the wire. Continuous annealing in front of the paint machine can not only achieve the purpose of softening oil, but also the annealed wire is straight, directly into the paint device, can apply a uniform paint film.

The temperature of the annealing furnace should be determined according to the length of the annealing furnace, the copper wire specification, and the wire speed. At the same temperature and speed, the longer the annealing furnace, the more the recovery of the conductor lattice. When the annealing temperature is low, the higher the furnace temperature, the better the elongation, but the annealing temperature will appear high, the higher the temperature, the smaller the elongation, and the surface of the wire lost gloss, and even easily crispy .

The annealing furnace temperature is too high, which not only affects the life of the furnace, but it is easy to burn the wire when the stop is tired. The maximum temperature of the annealing furnace is required to be around 500 ¡ã C. The stove is used in two-stage temperature control form, which is effective in selecting temperature in the position of static and dynamic temperatures. Copper is easily oxidized at high temperatures, and copper oxide is very crisp. The paint film cannot be securely attached to the copper wire, and copper oxide has a catalytic effect on the aging of the paint film. It has a negative impact on the softness, thermal shock, and thermal aging. . If the copper wire is not oxidized, it is necessary to contact the copper wire at a high temperature in contact with oxygen in the air, so there is a protective gas. Most annealing furnaces are sealed, and the other is open. There are three effects in the annealing furnace water tank: a closed furnace opening, a cooling wire, and a steam is a protective gas. Due to rare steam in the annealed tube, the air is not allowed to remove the air in time, and the water can be irradiated into a small amount of wine [**] solution (1: 1). (Take care of not a pure alcohol and control usage)

The water quality in the annealing sink is very important. The impurities in the water will make the wires do not clean the paint and cannot form a smooth paint film. The chlorine content of water in use is less than 5 mg / L, and the conductivity is less than 50 ¦Ì¦¸ / cm. The chloride ion is attached to the surface of the copper wire, causing the copper wire and the paint film after a period of time, producing a black spot on the surface of the wire in the paint lacquer film. To ensure that the quality must be cleaned regularly.

The water temperature in the sink also requires. Water temperature is advantageous for water steam to protect the copper wire in annealing, and the wire of the water tank is not easy to with water, but the cooling of the wire is unfavorable. Although the water temperature is low, there is a large amount of water on the wire, which is unfavorable to the paint. Typically, the thick wire temperature is low, and the fine wire is high. When the copper wire is in the surface of the water, it will indicate that the water temperature is too high. Generally, the thick wire is controlled at 50 to 60 ¡ã C, the centerwire is controlled at 60 to 70 ¡ã C, and the thin wire is controlled at 70 to 80 ¡ã C. The thin wire is fast due to speed, and the water is serious, and hot air drying should be used.