Why copper wire and aluminum wire can not be directly connected?

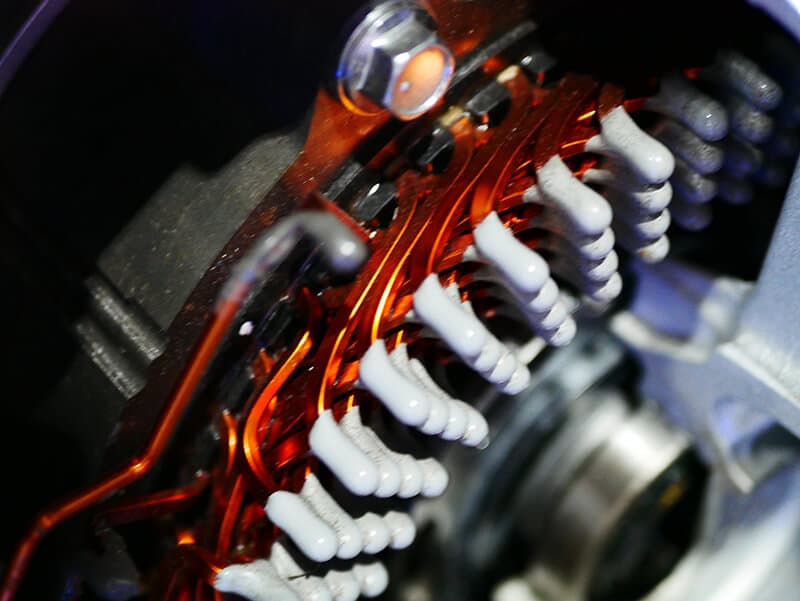

A brief introduction to the advantages and disadvantages of copper wire and aluminum wire:Same area:

1, copper wireis large load than aluminum wire . 2, copper wire is more flexible than aluminum wire. 3 copper wire is lower resistivity than aluminum wire. 4,copper wire is more stable than aluminum wire. 5, however, copper wirer price is 3.5 times higher than aluminum wire.

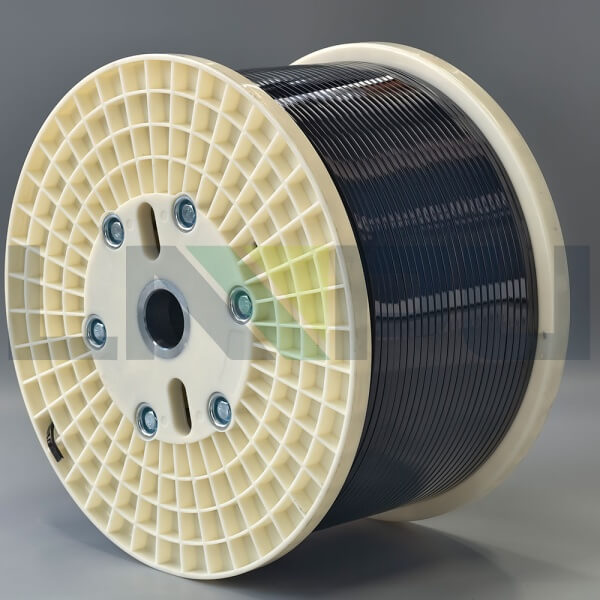

The chemical and physical properties of copper and aluminum are very different and should not be directly connected. However, copper and aluminum connection is inevitable. When they need to be connected, generally,to usethe copper and aluminum transition clamp, copper and aluminum transition joints, aftercopper wire or aluminum wiretinning ,then,directly connection.

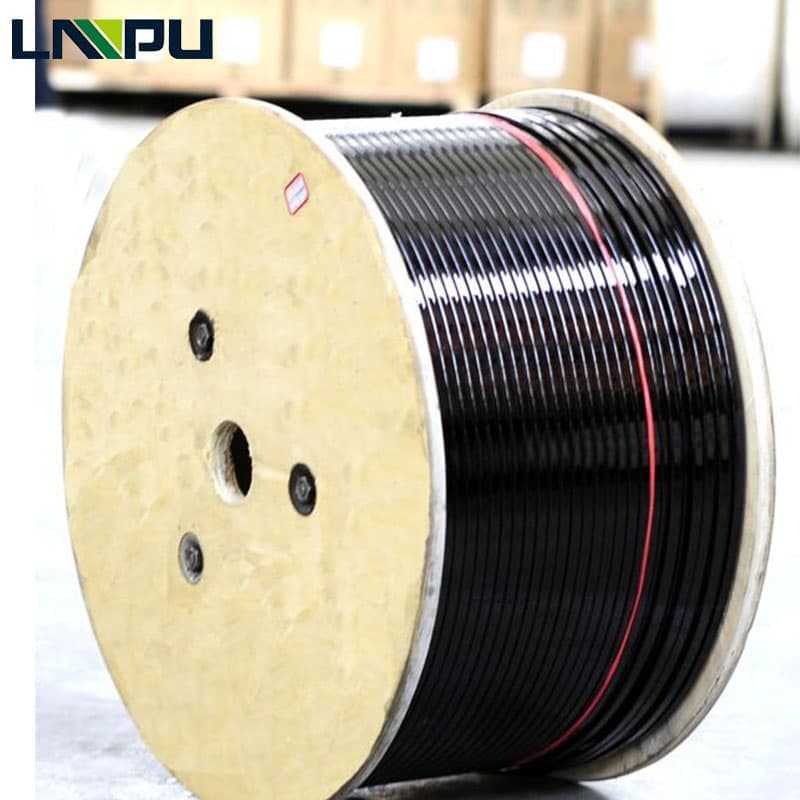

Because the copper and aluminum these two kinds of metal ‘s electrochemical properties are different. If they are directly connected, once touch the water, carbon dioxide or other impurities formed electrolyte, it formed a chemical battery. This due to the fact that aluminum tends to lose electrons to become negative pole and copper can hardly to lose electrons to become positive pole, thus forming a 1.69 V electromotive force between the positive and negative electrodes and passing a small current through it to corrode the aluminum wire, so-called galvanic corrosion. This will lead to poor contact between copper wire and aluminum wire, contact resistance increases.

When a current is passed, the junction temperature will increase, while the temperature increases and accelerates the joint corrosion, increasing the contact resistance, causing a vicious cycle until it burns down and even causes a fire.