Enameled Covered Aluminum Wire Production Process

Enamelled Covered Aluminium Wire Production Process

One step :

Take the pure aluminum material drawing into the aluminium rod wire;

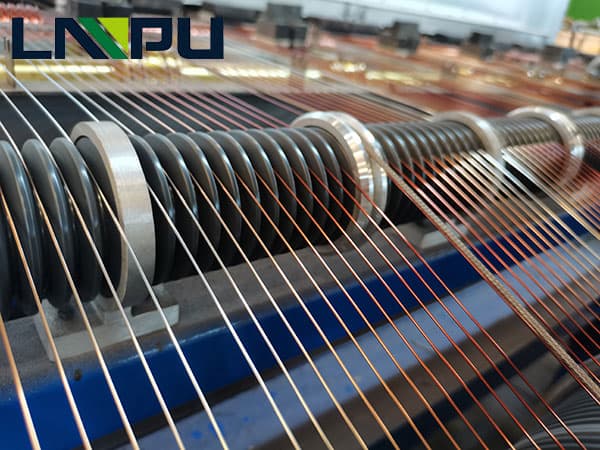

Two step :

Through the extrusion production line, take the aluminum rod wire into extruding and coarse drawing operation, then becoming the requirement specification of Bare aluminium wire;

Three step :

Take up the Bare aluminum wire conductor, and inspection the bare wire coil products;

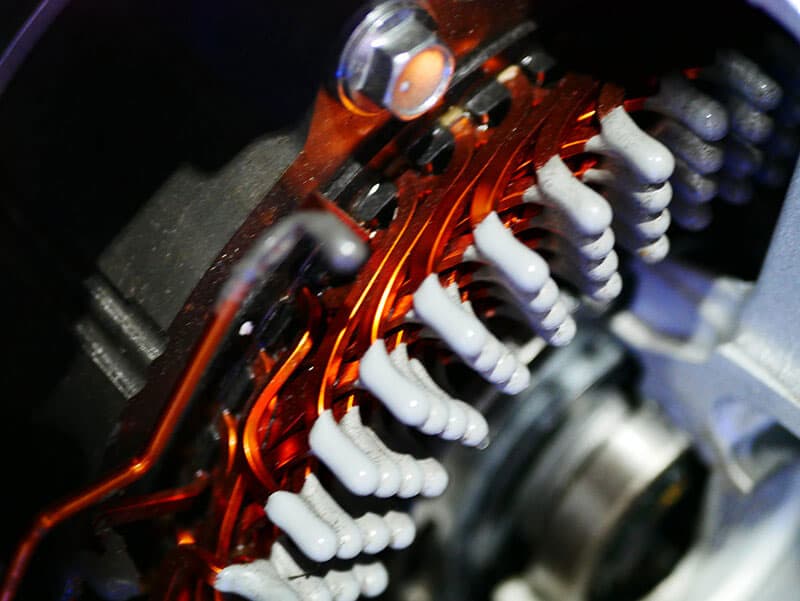

Four step :

Trough the enameled covered production line, taking cleaning¡¢annealing and drying operation , and ready to enameled covered step;

Five step :

Taking into enameling operation, and then for cooling and lubricanting;

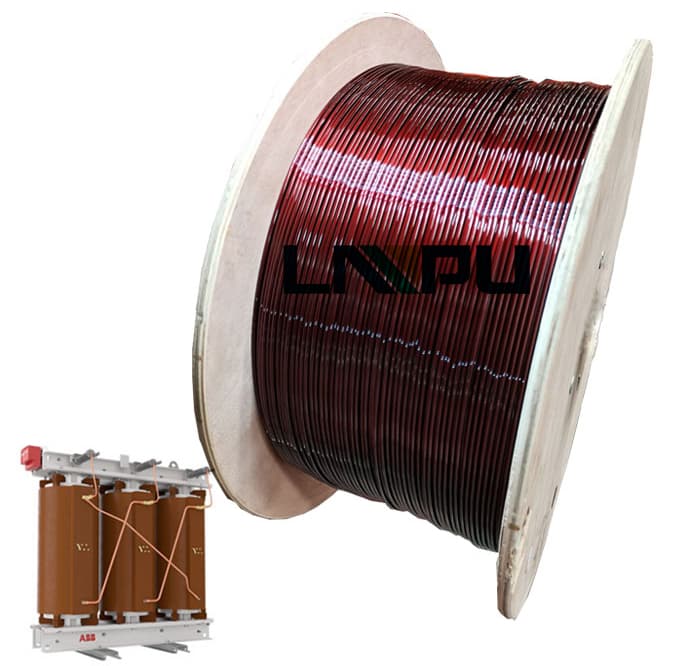

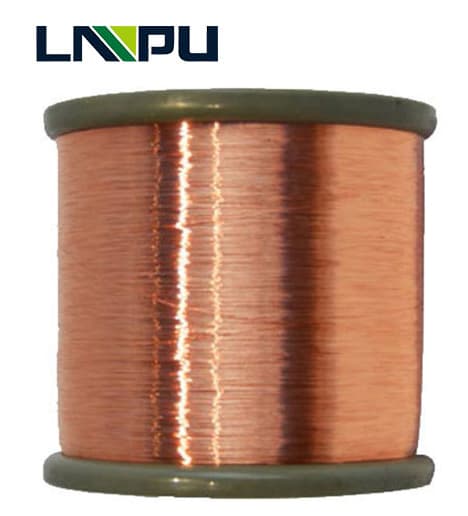

Six step :

Through the on-line monitoring equipment, inspecion the quality of enameled wire, and take up the fulfillment products.

Seven step :

Packing the enameled wire products, and placed neatly in warehouse.

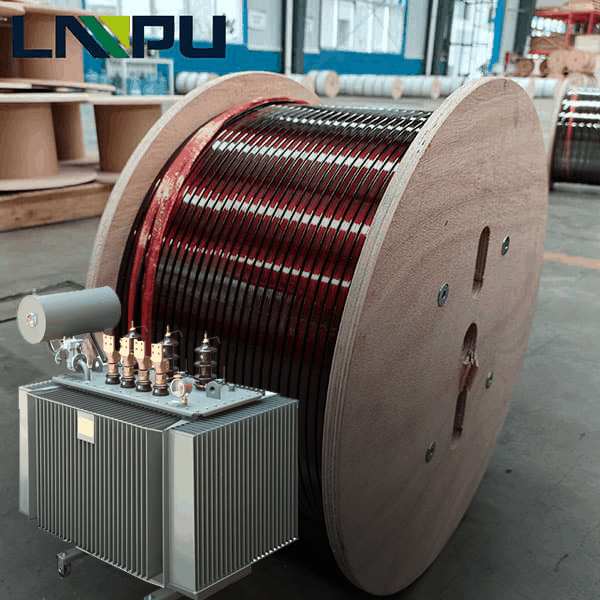

We manufacture a broad assortment of Enameled Aluminium Wires, which is an aluminum conductor, commonly known as aluminium stranded conductor.