Features and Application of enamel coated magnet wire

Application of enamel coated magnet wire

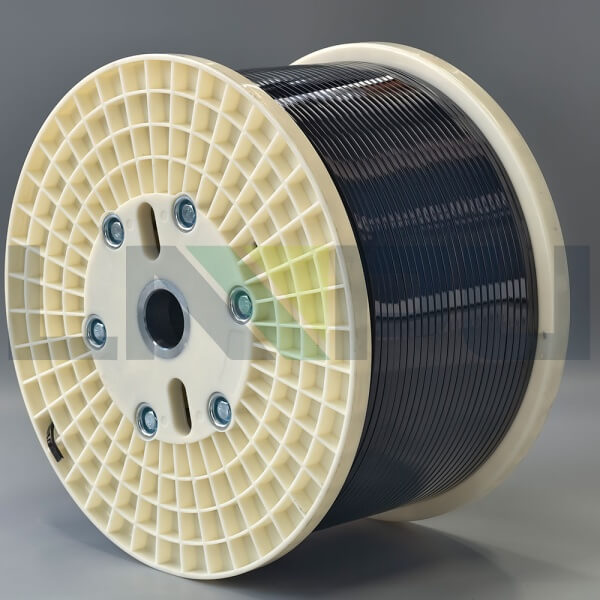

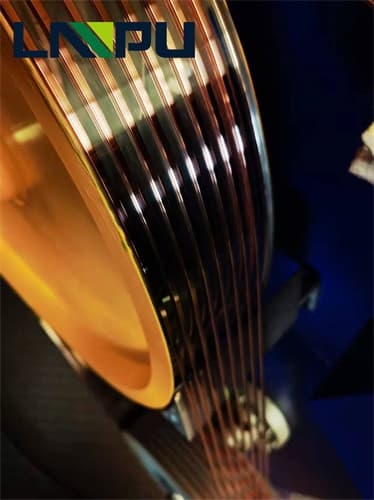

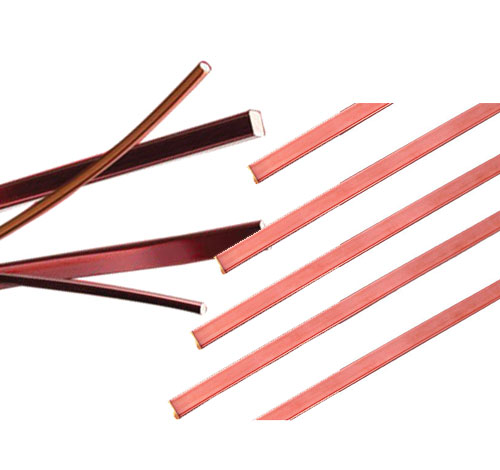

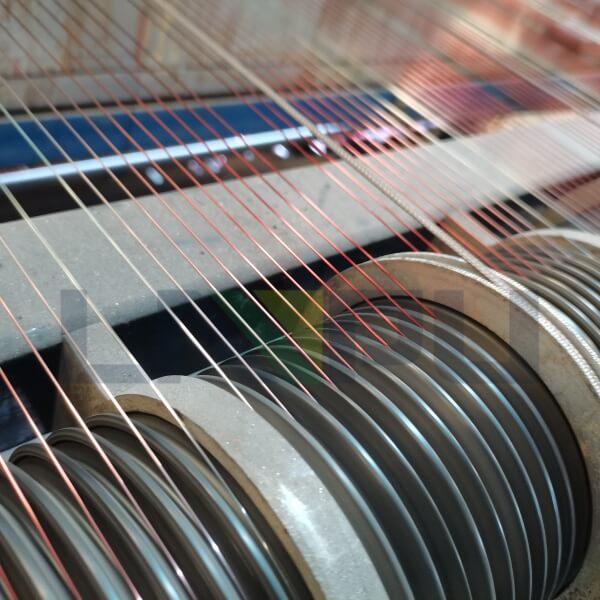

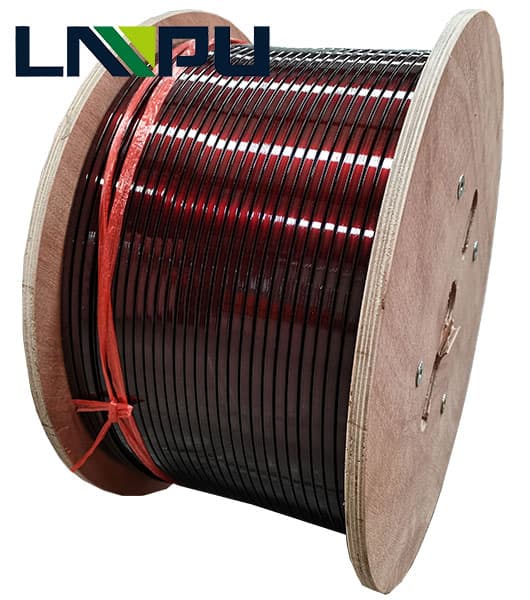

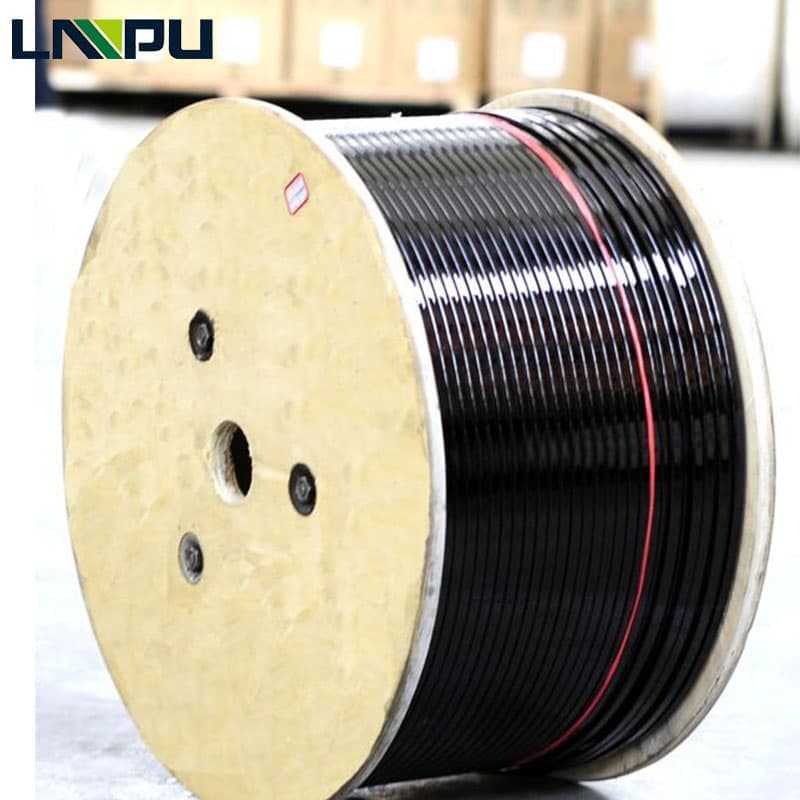

Wire for winding used in electrical equipment is generally called magnet wire. Simplyput,”enamel coated magnet wire is used for interchanging electrical energy with magnetic energy”.Magnet wires are broadly divided into enamelled wire (coating insulation), coveredconductor wire (fiber/film insulation), and combinations thereof.

Both magnet wire types as well as their performance are quite varied. Below the mostimportant features of magnet wires are listed:

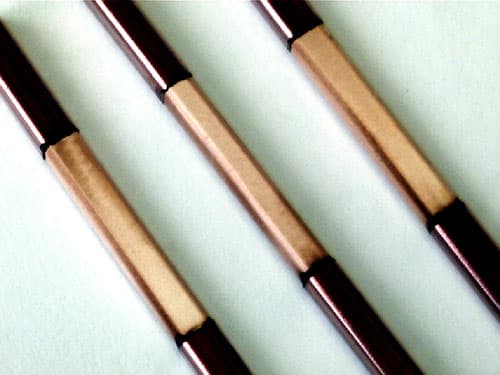

(a) Uniformity and degree of insulation

(b) Good electrical characteristics such as dielectric strength and insulation resistance(c) Resistant coating to mechanical stress induced by bending, stretching, and friction(d) Heat-resistance

(e) Resistant to solvents, chemicals and varnishes(t) Resistant to hydrolytic degradation

(g)Stable when combined with insulating material(h) Resistant to water and moisture

Any product will have particular strong properties in one or more of these features.Each type of wire has its own advantages and disadvantages. Therefore, it is importantto consider operating conditions in order to select the correct product.