What Is Magnet Wire Used For?

Magnet wire, also known as winding wire or enameled wire, is a critical component in many electrical devices and systems. Its unique properties make it indispensable in a wide range of applications, from small household appliances to complex industrial machinery. In this blog, we'll delve into the world of magnet wire, uncovering its uses, advantages, and why it's an essential material in the realm of electrical engineering.

What is Magnet Wire?

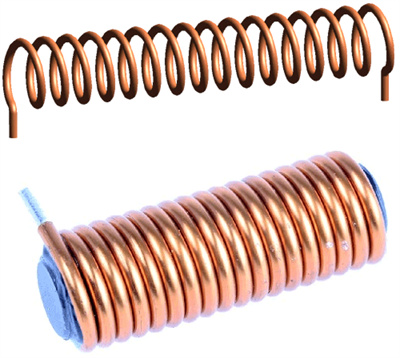

Magnet wire is a type of wire coated with a thin layer of insulation, typically made from a polyester or polyurethane enamel. This insulation serves to prevent the wire from short-circuiting when wound into coils or used in electrical devices. The core of magnet wire is typically made of copper, aluminum, or other conductive materials.

Applications of Magnet Wire

Electric Motors and Generators:

One of the most common uses of magnet wire is in electric motors and generators. The wire is wound into coils to create magnetic fields when an electric current passes through them. This interaction produces the rotational force necessary for the functioning of these devices.

Transformers:

Transformers play a crucial role in electrical distribution and power transmission. Magnet wire is used to wind the primary and secondary coils of transformers, allowing for efficient energy transfer between them.

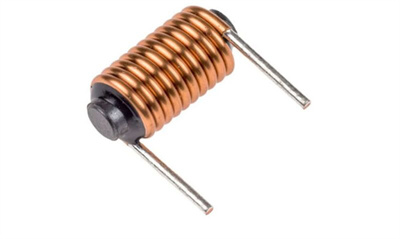

Inductors:

Inductors are passive electronic components that store energy in a magnetic field when an electric current passes through them. Magnet wire is used in the construction of inductors due to its ability to efficiently generate magnetic fields.

Solenoids:

Solenoids are electromechanical devices that convert electrical energy into linear motion. They are used in various applications, from controlling valves in automotive systems to door locks. Magnet wire is employed in the construction of solenoid coils.

Transformed Electronics:

Magnet wire also finds its way into various consumer electronics, such as speakers, headphones, and other audio equipment. In these applications, it is used to create magnetic fields that drive the movement of speaker cones.

Advantages of Magnet Wire

High Conductivity:

Copper, the most commonly used core material for magnet wire, is known for its excellent electrical conductivity. This property ensures efficient energy transfer and minimizes energy losses.

Thermal Stability:

Magnet wire is designed to withstand elevated temperatures, making it suitable for applications where heat is generated, such as in electric motors.

Compactness:

The thin insulation layer on magnet wire allows for more compact and lightweight coil designs. This is particularly important in devices where space is a limiting factor.

Durability:

The enamel insulation on magnet wire provides protection against environmental factors like moisture, chemicals, and abrasion, ensuring the wire's longevity.

Cost-Effectiveness:

Magnet wire offers an excellent balance between performance and cost, making it a preferred choice for a wide range of applications.

Conclusion

Magnet wire is a foundational component in the world of electrical engineering, enabling the efficient generation and transfer of magnetic fields. Its versatility and unique properties make it an essential material in a wide array of applications, from household appliances to complex industrial machinery. As technology continues to advance, the demand for magnet wire will likely continue to grow, driving further innovation in this critical field of electrical engineering.