What is the difference between bare wire and enameled wire?

Wires are the unsung heroes of our modern world, serving as the nervous system that powers our devices and systems. While they might seem simple, there are various types of wires designed to fulfill specific functions. Two such types are bare wire and enameled wire. These wires, although sharing the same basic purpose of conducting electricity, possess distinct characteristics that make them suitable for different applications. In this blog, we will delve into the differences between bare wire and enameled wire, their unique features, and their respective applications.

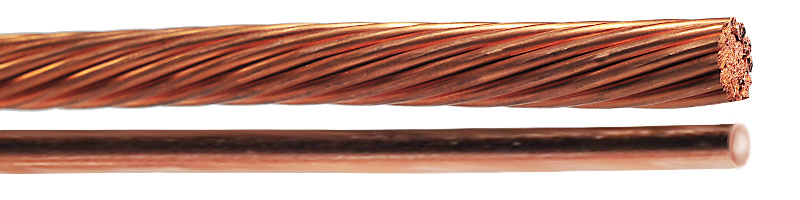

Bare Wire:

Bare wire, as the name suggests, is a wire that does not have any form of insulating coating or covering. It consists solely of the conductive material, usually copper or aluminum. This simplicity in design offers both advantages and limitations.

Advantages:

Conductivity: Bare wires are excellent conductors of electricity due to their direct contact with the conducting material. This makes them ideal for applications where minimal resistance is crucial, such as grounding systems.

Cost-Effectiveness: Since there is no need for an insulating coating, bare wires are generally less expensive to produce. This cost-effectiveness makes them a popular choice for large-scale projects where budget constraints are a concern.

High Current Applications: The absence of an insulating layer allows bare wires to handle higher current loads without the risk of overheating or melting.

Limitations:

Risk of Short Circuits: Without insulation, there's a higher risk of bare wires coming into contact with each other or other conductive materials, potentially leading to short circuits, electrical faults, or safety hazards.

Corrosion: Bare wires are more susceptible to corrosion, as there is no protective layer to shield them from environmental factors like moisture, chemicals, or contaminants.

Enameled Wire:

Enameled wire, on the other hand, consists of a conductive core, often made of copper, coated with a thin layer of insulating enamel. This enamel coating serves as a protective barrier that provides numerous benefits and widens the range of applications for this type of wire.

Advantages:

Insulation: The primary advantage of enameled wire is its insulating property. The enamel coating prevents direct contact between the conducting material and other wires or surfaces, reducing the risk of short circuits and enhancing safety.

Corrosion Resistance: The enamel coating acts as a barrier against moisture, chemicals, and other corrosive agents, extending the lifespan of the wire and making it suitable for outdoor or harsh environments.

Space-Efficiency: Enameled wire's insulation is thin yet effective, allowing for compact winding and space-saving in applications such as transformers, motors, and solenoids.

Customizability: The enamel coating can be tailored to meet specific electrical, thermal, or mechanical requirements, making enameled wire versatile for various applications.

Limitations:

Lower Conductivity: The enamel insulation introduces a small layer of resistance, which might be a concern for applications that demand extremely high conductivity.

Delicate Handling: The thin enamel coating can be susceptible to damage if mishandled or exposed to harsh mechanical stress.

Applications:

Bare Wire: Grounding systems, electrical connections in some industrial applications, and certain types of antennas.

Enameled Wire: Transformers, motors, solenoids, inductors, speakers, and various electrical components where insulation and space efficiency are essential.

In conclusion, both bare wire and enameled wire have their distinct roles in the realm of electrical systems. Bare wire excels in high-conductivity and cost-effective applications, while enameled wire shines in scenarios that demand insulation, corrosion resistance, and space efficiency. The choice between these two types of wires depends on the specific requirements of the project, highlighting the importance of understanding their differences to make informed decisions in various engineering and electrical applications.