Home » enameled aluminum wire » China Top Quality Enameled Copper Clad Aluminum Wire Factory Price

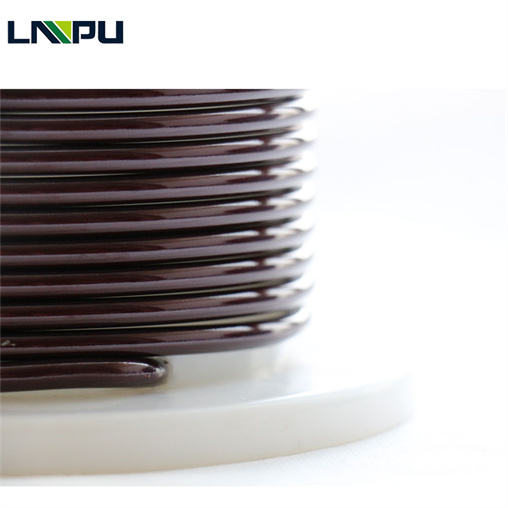

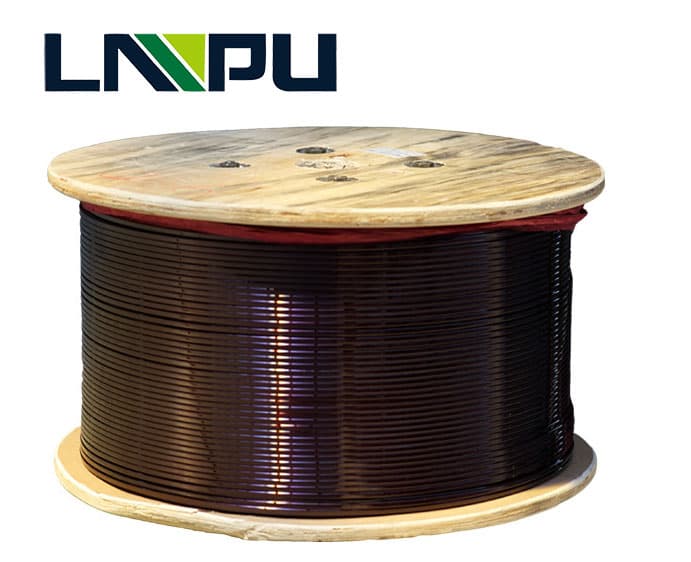

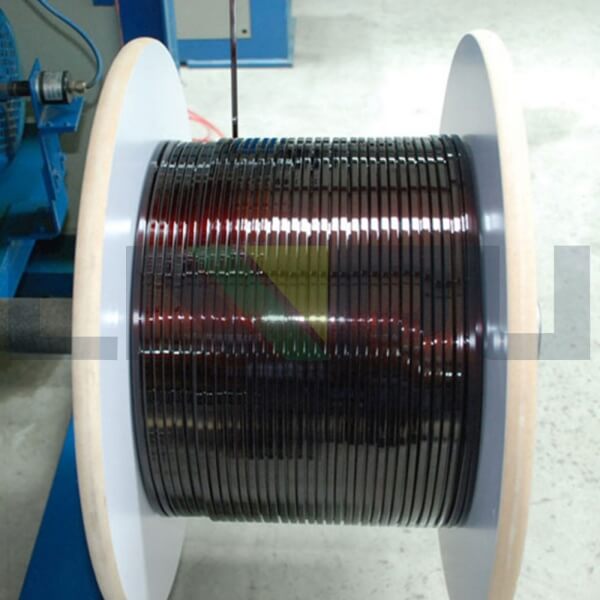

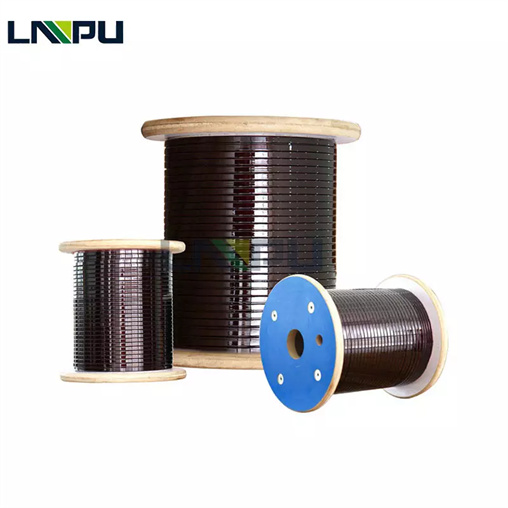

China Top Quality Enameled Copper Clad Aluminum Wire Factory Price

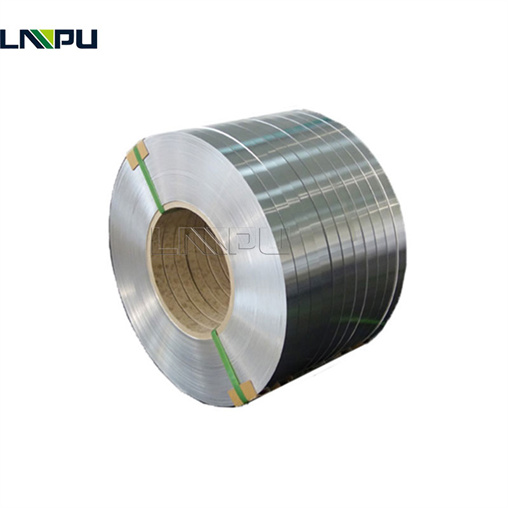

Conductor Type: Solid

Delivery time: 7-30 Days

Thermal Class: 130-220C

Brand Name: LP Magnet Wire

Bobbin: 30kg/50kgWooden Spool

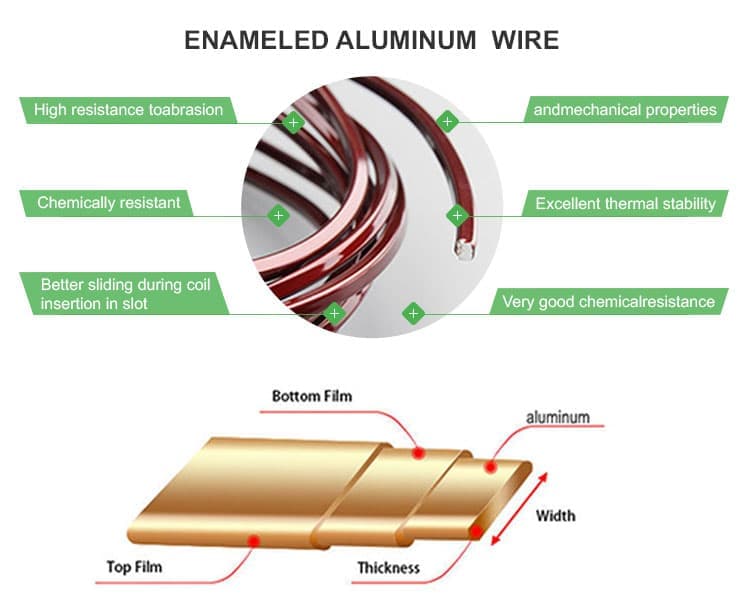

Insulation: PEW, PIW, EIW, AIW, EI/AIW

Contact US

Get Price

Share:

Content

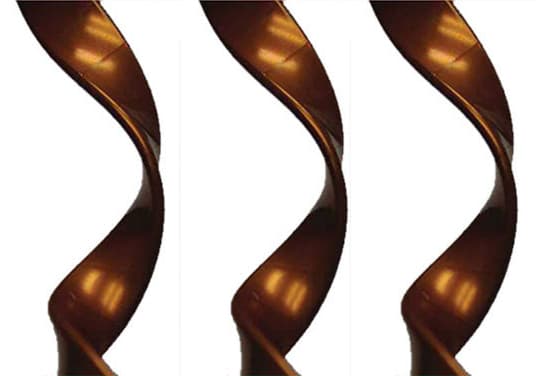

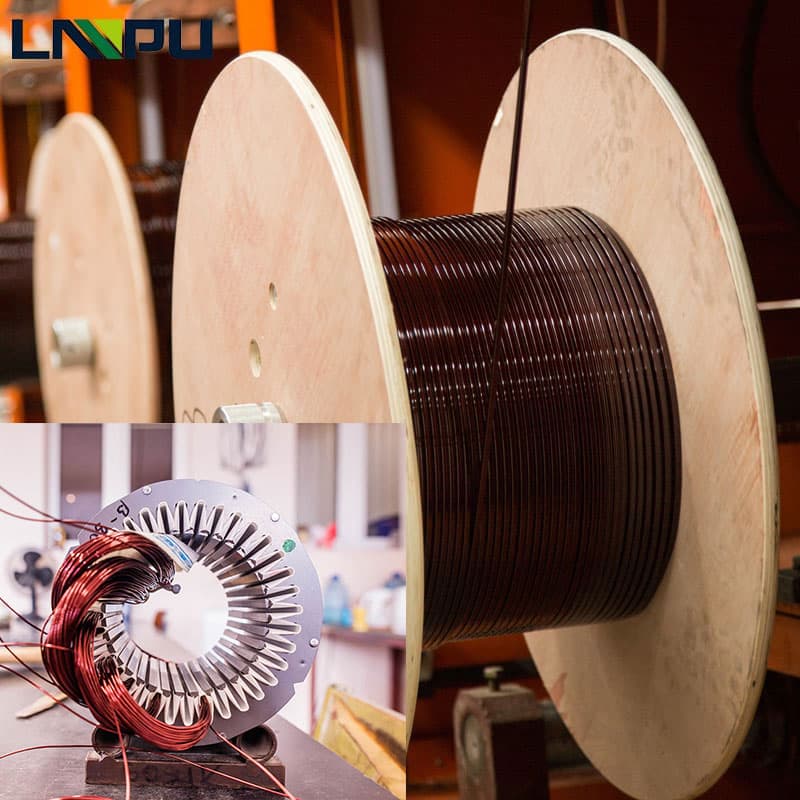

Enameled Copper clad aluminum wire adopts advanced cladding welding manufacturing technology

| Enameled Type | Polyester | Modified Polyester | polyester-imide | Polyamide-imide | polyester-imide /Polyamide-imide |

| Insulation Type | PEW/130 | PEW(G)/155 | EIW/180 | EI/AIW/200 | EIW(EI/AIW)220 |

| Thermal class | 130, CLASS B | 155, CLASS F | 180, CLASS H | 200, CLASS C | 220, CLASS N |

| Conductor | CCA | CCA | CCA | CCA | CCA |

| Size(mm) | 0.19-4.0 | 0.19-4.0 | 0.19-4.0 | 0.19-4.0 | 0.19-4.0 |

| Enamel thickness | Grade(0,1,2,3) | Grade(0,1,2,3) | Grade(0,1,2,3) | Grade(0,1,2,3) | Grade(0,1,2,3) |

| Standard | IEC60317-0-2 IEC60317-29 MW36-A SZ Enterprise standard SJ/T11223-2000 |

IEC60317-0-2 IEC60317-29 MW36-A SZ Enterprise standard SJ/T11223-2000 |

EC60317-0-2 IEC60317-29 MW36-A SZ Enterprise standard SJ/T11223-2000 |

IEC60317-0-2 IEC60317-29 MW36-A SZ Enterprise standard SJ/T11223-2000 |

IEC60317-0-2 IEC60317-29 MW36-A SZ Enterprise standard SJ/T11223-2000 |

Inquiry

More enameled aluminum wire