How to wind wire in high and low voltage motors?

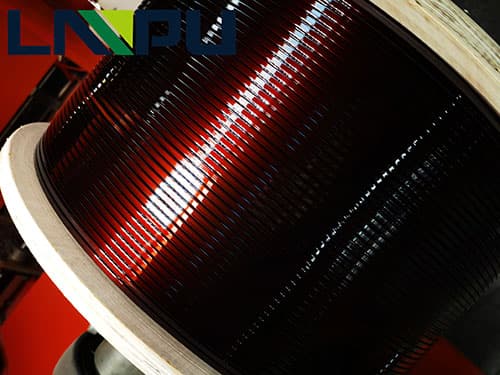

High-voltage motors need to use diimide, monoimide, single-thin double-wire and other wire-wrapped flat wires of various specifications according to the voltage level. The straight part is 25 cm, and the maximum coil straight part is 1.2 meters. The winding can be single flat winding, single vertical winding, double flat transposition winding, or double flat transposition vertical winding, which is determined according to specific requirements. Round enameled wire coils can also be wound using the universal adjustment in the disc. The winding machine has a built-in speed regulating motor and a turbo reducer, which drives the winding machine to achieve 0-120 rpm reversible and brakeable rotation, and can count forward and reverse, generally 1600KW can be wound All kinds of motor coils within the range are also equipped with a set of simple tensioners, which can control the tightness of the winding coils. General repair manufacturers can choose the above products. If they encounter special large-scale specifications, they can choose special type windings. equipment.