Manufacturing process of magnet wire

7 step of manufacturing of magnet wire: Material preparation, Drawing, Wash with water, Annealing, Impregnation, dry, Take-up and Packing and storage

1. Material preparation

The raw material of the magnet wire is transported to the production site by cart. The preparation of the insulating varnish is completed in the paint configuration room. According to the different degree of insulation of various magnet wires, a certain proportion of paint and thinner are fully mixed and evenly added to the enameling machine.

2. Drawing

The wire drawing is carried out in the wire drawing machine, and it is made by drawing one time or multiple times according to the required wire diameter. The temperature during drawing can generally reach 60-100¡ãC. Water-soluble lubricants are used for lubrication and cooling. When the temperature exceeds 100¡ãC, supplementary cooling and heat removal are performed.

3. Wash with water

Water washing is the use of water purified by hydrochloric acid and caustic soda to flush the electromagnetic wire with a high-pressure water stream to remove the oil on the surface.

4. Annealing

Annealing is generally carried out in an annealing furnace by means of electric heating, and the annealing temperature is generally controlled at 300-600¡ãC, and water vapor is used for protection during annealing to prevent oxidation. After annealing, use a blower for air cooling, and enter the impregnation section at about 40¡ãC.

5. Impregnation

The dipping section is carried out in an enameling machine and completed several times according to the requirements of the insulating layer. When dipping, add the appropriate proportion of diluent according to the needs of the coating. The thinner contains flammable and poisonous liquids such as cresol and xylene.

6. dry

The electromagnetic wire is dried in a drying oven, and the drying temperature is determined by the wire drawing speed, generally 300-400¡ãC. The highest can reach 670 degrees Celsius. Drying and exhaust gas removal are performed simultaneously. The exhaust gas (temperature 300-400 degrees Celsius) contains toxic and flammable vapors such as cresol, phenol and xylene. After the catalytic reaction reaches the environmental protection index, the exhaust fan is discharged into the atmosphere.

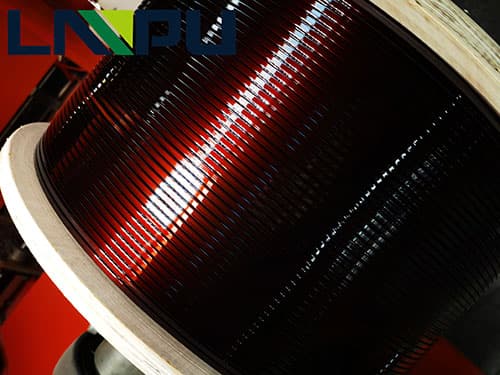

7. Take-up

Take-up is the use of a take-up device to wind the dried electromagnetic wire on the wire reel. A small amount of lubricant (974 gasoline, cyclohexane) should be added when taking up the thread.

8. Packing and storage

After passing the inspection, pack the wound wire reel with plastic film into a carton or paper tube, pack it into a wire drag according to the user’s needs, and load and unload it into a dedicated warehouse.