How to judge quality of Enameled wire?

After the product is manufactured, whether its appearance, size and performance meet the requirements of the technical standards of the product and the technical agreement of the user must be judged by the inspection beam and measured; the test shall be compared with the technical standard of the product or the technical agreement of the user and meet the requirements If it is qualified, otherwise, it is unqualified. Passing the inspection can reflect the stability of the enameled wire product quality, the material and the rationality of the process. Therefore, the quality inspection has the function of checking, preventing and identifying.

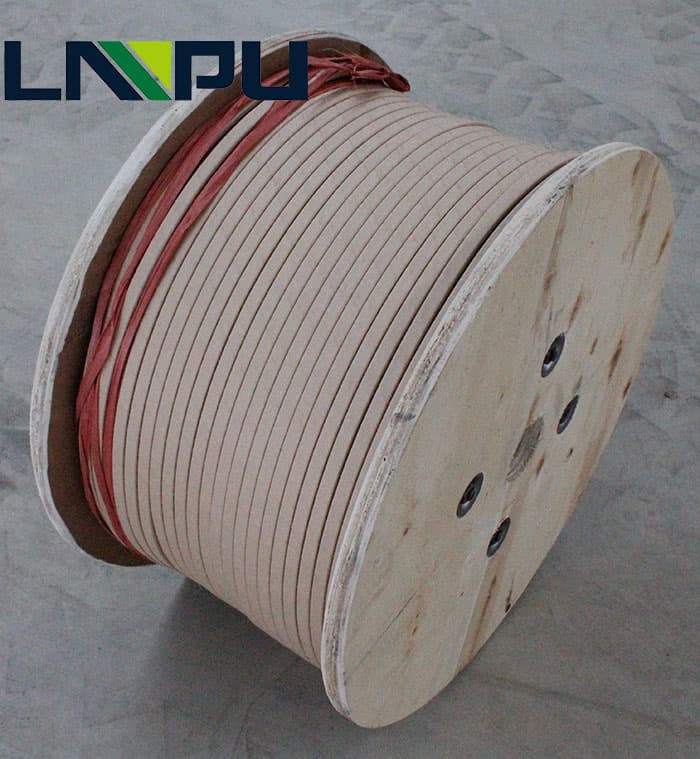

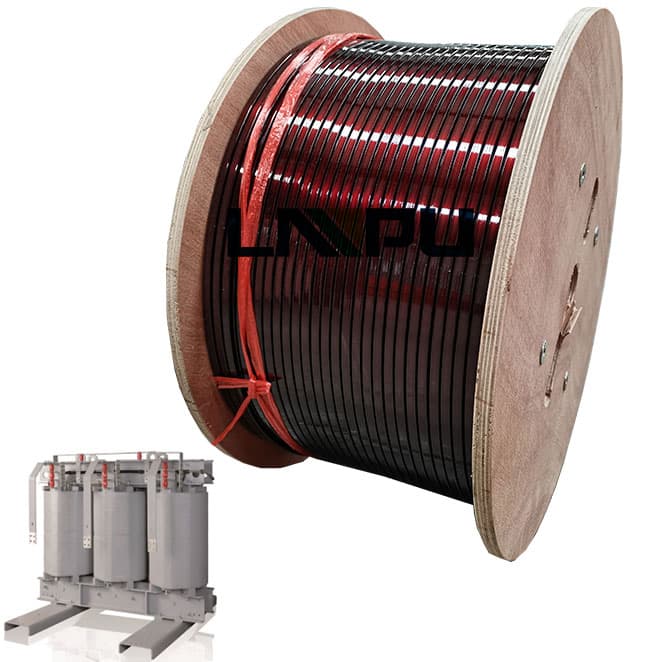

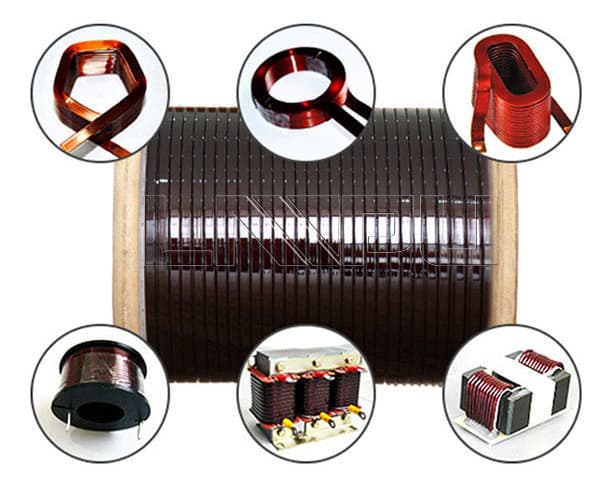

The contents of the enameled wire inspection include; appearance and size inspection and measurement, and performance testing. The properties include: mechanical properties, chemical properties, thermal properties and electrical properties. Now we mainly explain the appearance and size.

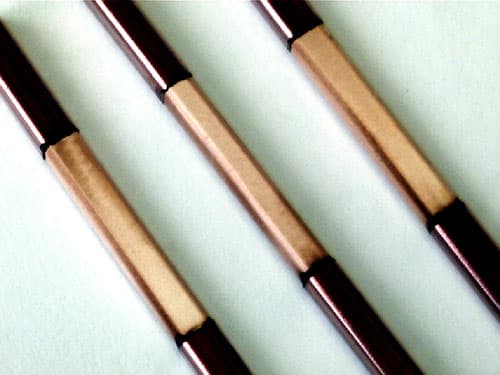

1. The surface (appearance) of the enameled wire should be smooth, uniform in color, no particles, no oxidation, hair, yin and yang, black spots, paint stripping and other defects that affect performance. There are many factors that affect the surface of the press line, retractable freely, and it is related to factors such as raw materials, paint, equipment, technology, and environment.

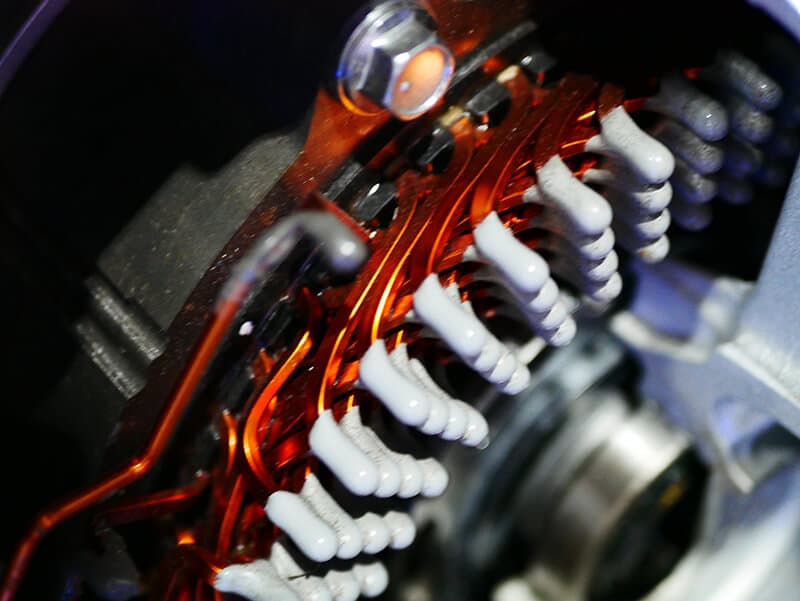

2. Size: The size of enameled round wire includes: external dimension (outer diameter) D conductor diameter In the production process of d motor, welding is one of the most important processes in motor manufacturing, enameled wire and enameled welding, enameled wire and lead wire welding. The quality of welding directly affects the performance, safety and service life of the motor.