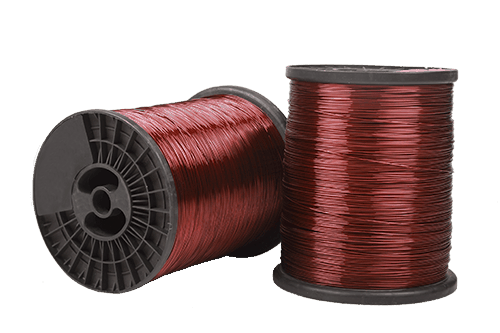

Painting method for enameled wire

The paint is a process of painting the paint of the enameled wire to form a uniform lacquer layer of a thickness on the metal conductor. This is related to several physical phenomena and painting methods of liquid.

Viscosity When the liquid flows flows, the molecules collide with each other, bringing a layer of molecules with another layer of molecular motion, and since the mutual force has caused the latter molecule to hinder the motion of the previous layer, by This exhibits the ability of the activity, which is called viscosity. Different painted methods, different wire specifications are different from the viscosity requirements of the paint. The size of the viscosity is mainly related to the size of the molecular weight of the resin, the resin molecular weight is large, the viscosity of the paint is large, which is used to coat the thick wire because the mechanical properties of the paint film having a large molecular weight are better. The small viscosity is used for coating fine wires, and the molecular weight of the resin is easy to apply well, and the paint film is smoother. There is a molecule in the surrounding molecules inside the surface tension liquid, and the gravity between the molecules can reach the temporary balance, and a layer of molecules in the surface of the liquid surface, and the one hand is protected from liquid molecules, and its force is to point to the depth of the liquid. On the other hand, the gas molecules are attracted, but the gas molecules are less than the liquid molecules, and the molecules of the liquid surface layer are largely protected from the inside of the liquid, so that the surface of the liquid is contracted as much as possible to form a bead shape. The surface area of u200bu200bthe spherical shape in the same volume of geometric shape is minimized, and if the liquid is not subject to other forces, it is always spherical under surface tension. According to the surface tension of the surface of the lacquer, the curvature of the uneven surface is different, the positive pressure of each point is unbalanced, before entering the enameled furnace, the thickness is flowed to thin, so that The lacquer is uniform. This process is called the leveling process. In addition to the impact of the paint film, it is also affected by the effects of gravity.

After the lacquer wire is felt, there is a pull-up process. Because the wire is painted, the lacquer is olived after the paint is olive. At this time, the viscosity of the lacquer itself is evolved under the surface tension, and transforms in an instant to a circular shape.

When the specifications of the wire are small, the viscosity of the paint is small, and the time required is small; if the wire size is increased, the viscosity of the paint also increases, the time required to pull the circle Larger. In high viscosity paints, sometimes surface tension cannot overcome the inner wear of the paint, resulting in uneven lacquer layers.

After the lacquer wire felt, there is a problem with gravity effect during the pulling of the lacquer layer. If the puller is very short, the tip of the olive category disappears quickly, and the gravity effect is very short, and the lacquer layer is relatively uniform. If the pulling is longer, then the tone of the two ends has a long time, the gravity action time is also longer, and the lacquer layer at the sharp angle has a trend of downs, so that the local area lacquer is thickened, surface Tension has caused the paint to pull a spherical shape, and become a particle. Since the gravity acts in the thickness of the paint layer, it is very prominent, so it is not possible to apply too thick, which is one of the reasons for “paint multi-coating”” when the lacquer wire is applied.

When the wiring is applied