Production process of enameled copper wire

Pay-off (link pull) ¡ú annealing ¡ú painting ¡ú baking ¡ú cooling ¡ú lubrication ¡ú take-up

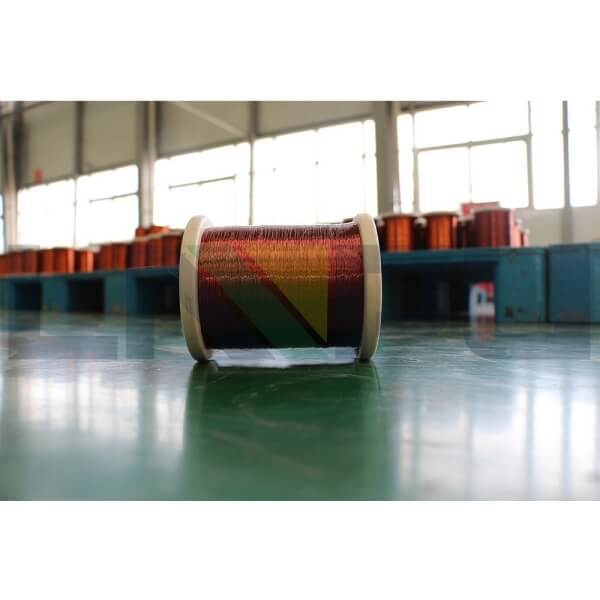

1. Pay-off: release the copper material evenly from the iron shaft to provide raw materials and ensure the stability of the painting. On a high-speed machine, a combined wire drawing machine is used to pay off the wire.

2. Annealing: soften the bare copper wire, remove the internal stress in the stretching process, rearrange the molecular lattice, and enhance flexibility and conductivity.

3. Paint: Apply insulating paint evenly to bare copper wire, relying on mold or felt as a medium

4. Baking: Evaporate the solvent in the paint solution to solidify the paint base material to form a paint film with a solid body structure.

5. Cooling: Allow the paint film to cool down and further shape it to prepare for the second painting.

6. Lubrication: Apply a layer of lubricant to the enameled wire after painting to reduce friction during processing.

7. Take-up: use a plastic shaft to take up the finished product after processing and arrange it evenly, which is convenient for customers to process and use.