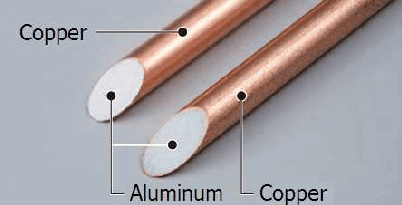

Triple insulated aluminum wire

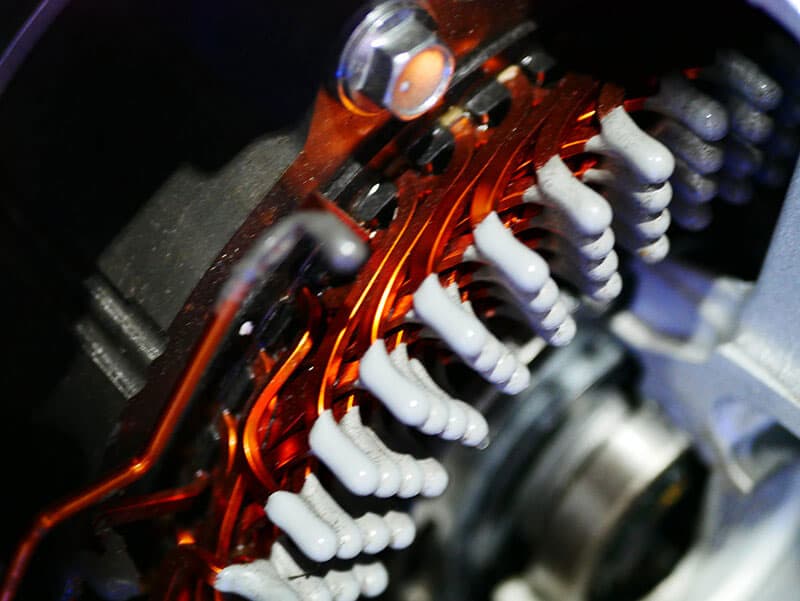

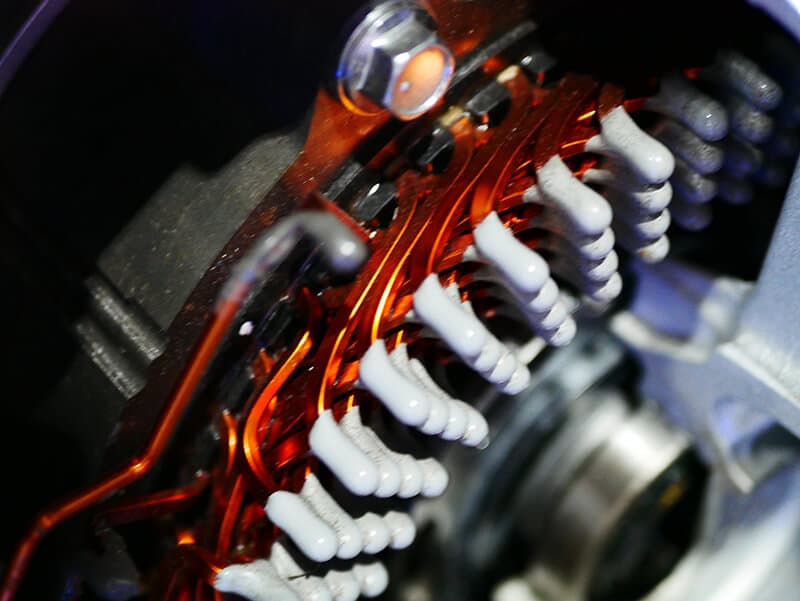

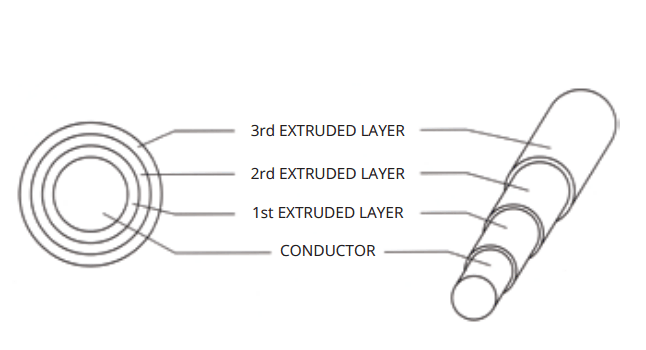

The main advantage of the TIW wires is relatively high electric strength of the insulation, with breakdown voltage min. 6kV. Obtaining such a high resistance was possible by the use of a reinforced, three-layer conductor insulation. Third external insulation made of polyamide gives excellent flexibility and high mechanical resistance of the wire. Normally, TIW wires are produced in thermal class B. Fully automated manufacturing process provides a central position of conductor and the same thickness of insulation at any point of the wire.

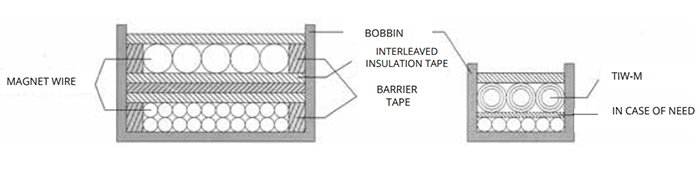

Reinforced insulation causes the TIW wires meet the technical requirements of UL1950, IEC60950, BSEN60950 on creepage distance. Thus, it is unnecessary to use the margins of insulation in transformers, which ensure the required insulation distance. Using TIW wires can also reduce the number of insulation layers between windings and avoid the use of sleevings.

Features :

1. Consist of three layers of insulation. Completely isolate the primary winding from the secondary winding of transformers.

2. Greatly reduce the size and weight of transformers.

3. Greatly improve the efficiency of the transformer by reducing the distance between coils.

4. Allow to wind directly on the top of enameled wires.Eliminate the interleaved insulation tapes,barriers and insulating sleeves.

5. Solderable without the need of insulation pre-stripping.

6. Can be fast coiled by using an Automatic Coiling Machine.

7. Thermal Resistance Class B(130C) and Class F(155C),are available.

8. Self-Bonding type has a self-bonding layer that covers the outer surfce.The bobbin can be eliminated and the size and weight of transformers can be further reduced.

9. Litz wire type has high frequency resistance that can sharply reduce the power losses caused by skin and proximity effect and is suitable for high frequency tranfformers.

10. Conform to isolation requirement of safety standard UL1950/UL2353/EN60950.

All this leads to a significant reduction costs of the transformer, increase efficiency and miniaturization of the device. Depending on the design, the use of wire TIW may reduce the overall dimension of the transformer to 40%, and weight up to 60% compared to the transformers wound enameled wires.

Soldering process can be performed without a mechanical stripping of insulation. It only requires to maintain the appropriate temperature and time of soldering.

Application :

Widely used in transformers in Switched Mode Power Suppliers(SMPS)/AC Adapters/AC Chargers.