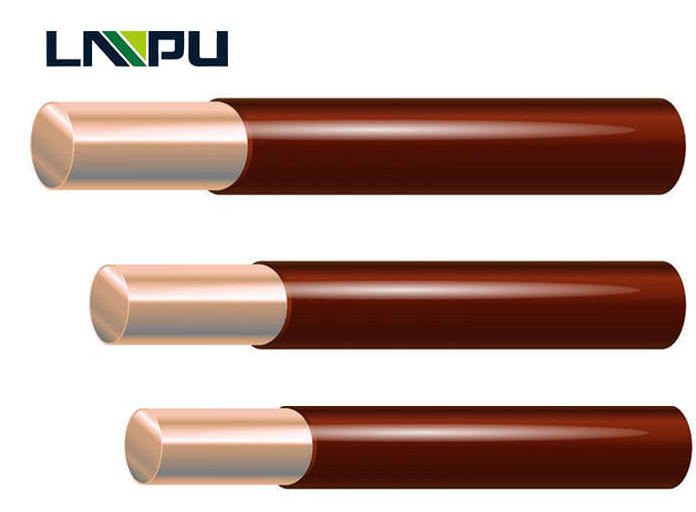

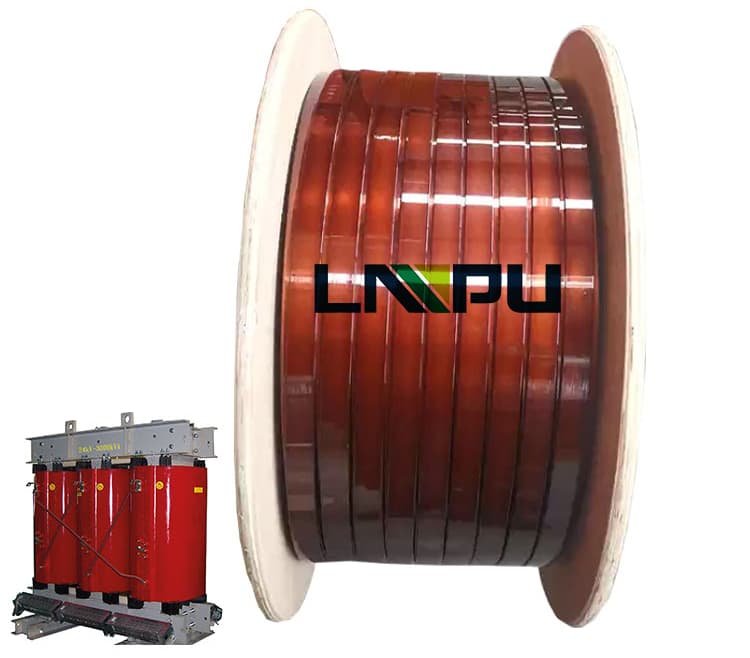

Aluminum Enameled Electric Wire 1.5mm For Moxico

Features of Aluminum Enameled Electric Wire 1.5mm For Moxico

1) Excellent bending performance

2) High flexibility of enamel

3) Good wear resistance

4) High mechanical properties

5) Higher thermal performance

6) Good resistance to refrigerants and Freon

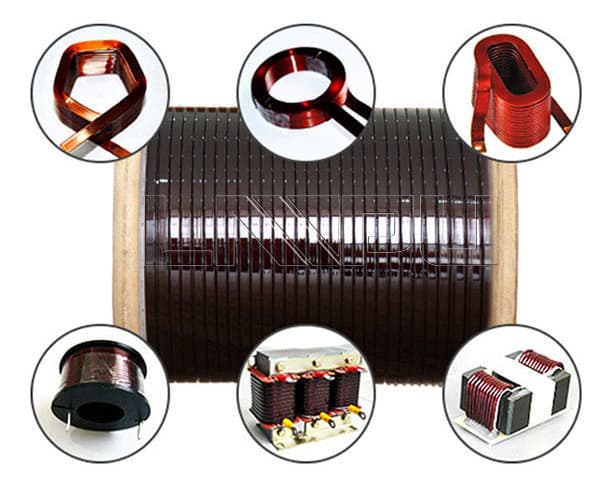

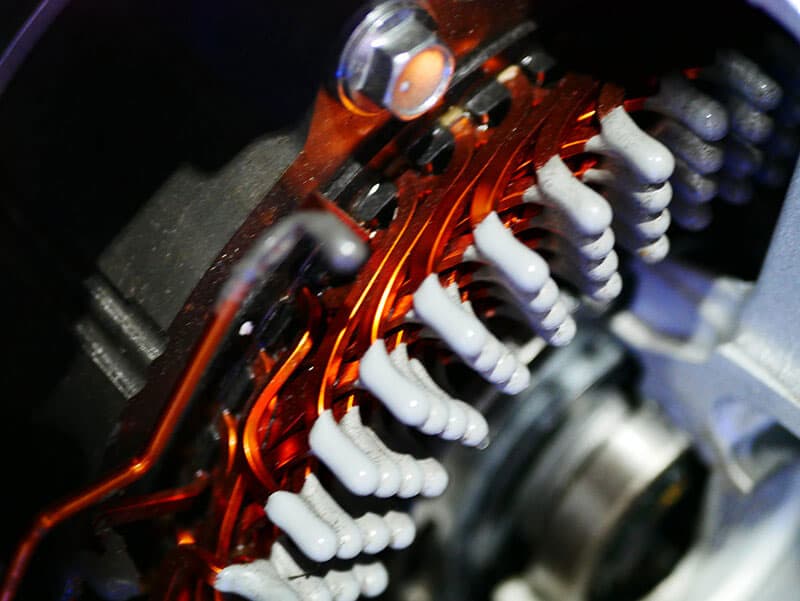

7) Suitable for windings subjected to continuous high temperature and mechanical stress

8) Good chemical resistance

9) Excellent mechanical and chemical properties

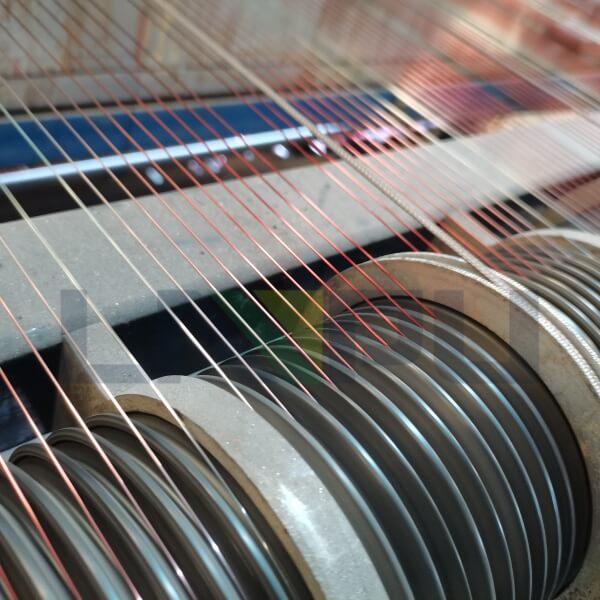

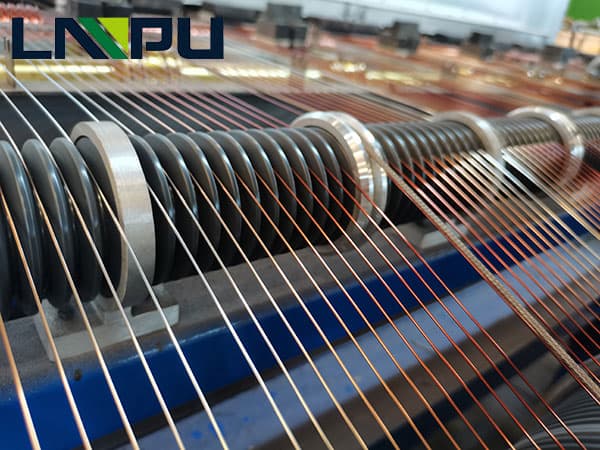

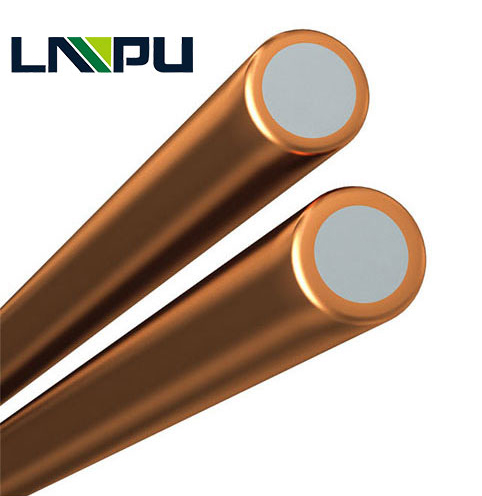

As the conductor of enameled wire, aluminum wire is different from copper wire in processing. It has its special difficulties. In the process of drawing, due to its low tensile strength, it is very easy to break during the drawing process. In addition, the hardness and wear resistance are not as good as Copper, so the surface is easily scratched, and the surface of the coated enameled wire often has many bright spots, beads, and aluminum dew points. At present, the minimum drawing of aluminum wire used for enameled wire is ¦Õ0.15mm. In addition to the poor surface finish in wire drawing, the oil stains and heavy aluminum powder on the surface are another problem. For comprehensive analysis, it is necessary to carry out transformation, analysis, testing and research on the selection of equipment and tooling, the ratio of molds, and the formulation of lubricating fluid. Effectively overcome the shortcomings of frequent wire breakage, surface oil stains and poor finish when other wire drawing lubricants at home and abroad are used. Lubrication should be able to reduce the coefficient of friction between steel and aluminum and aluminum and aluminum, and it has a powerful cleaning function for aluminum powder and oil stains.