Copper paint package production process principle

Copper paint package wire production process principle

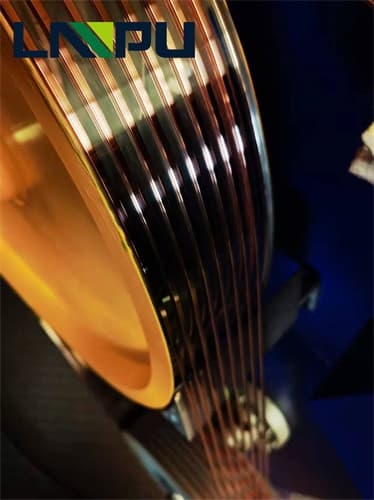

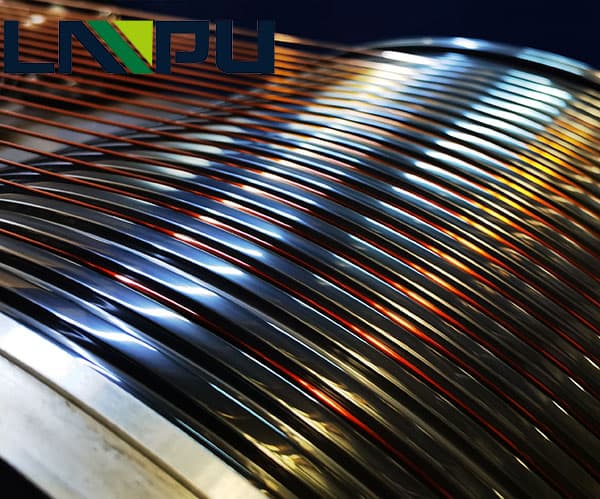

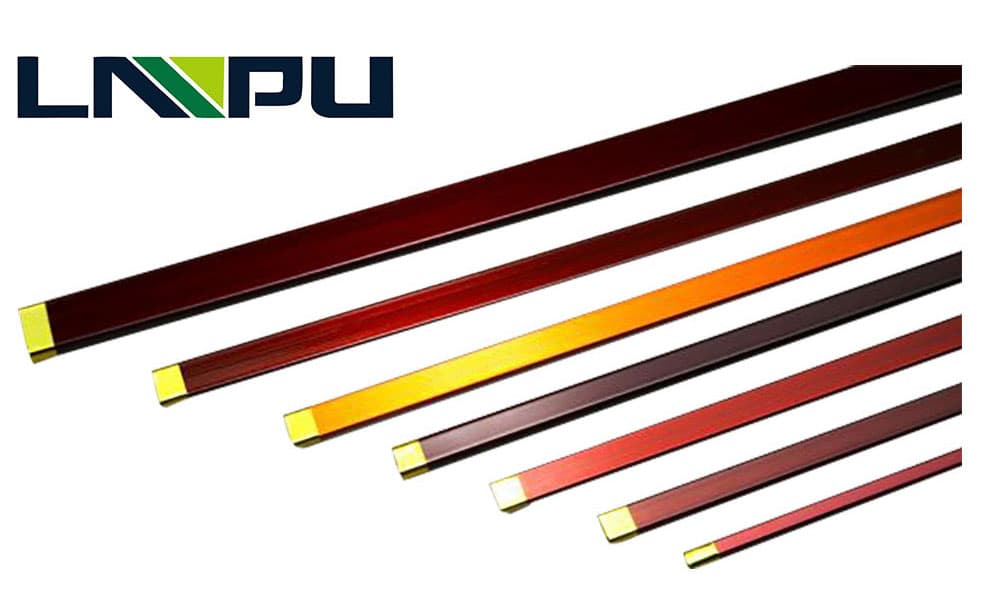

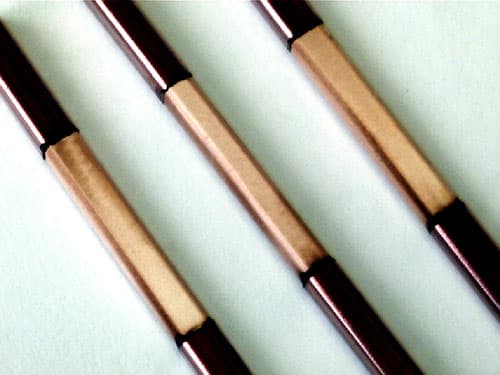

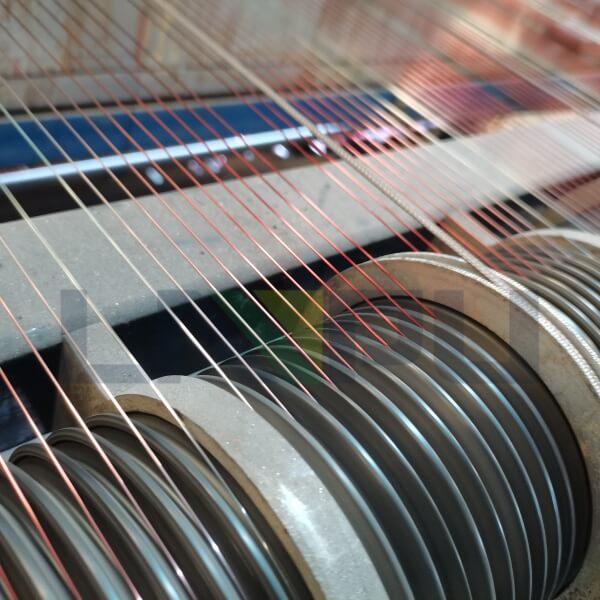

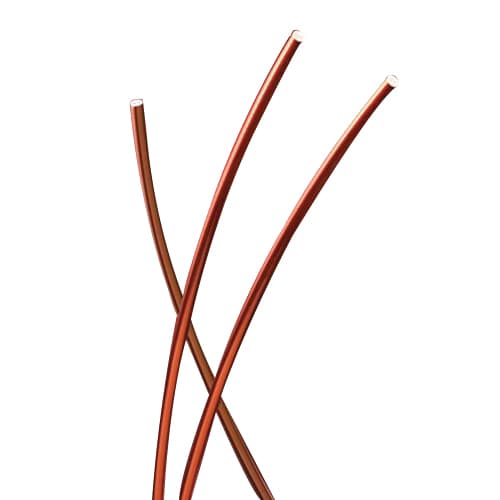

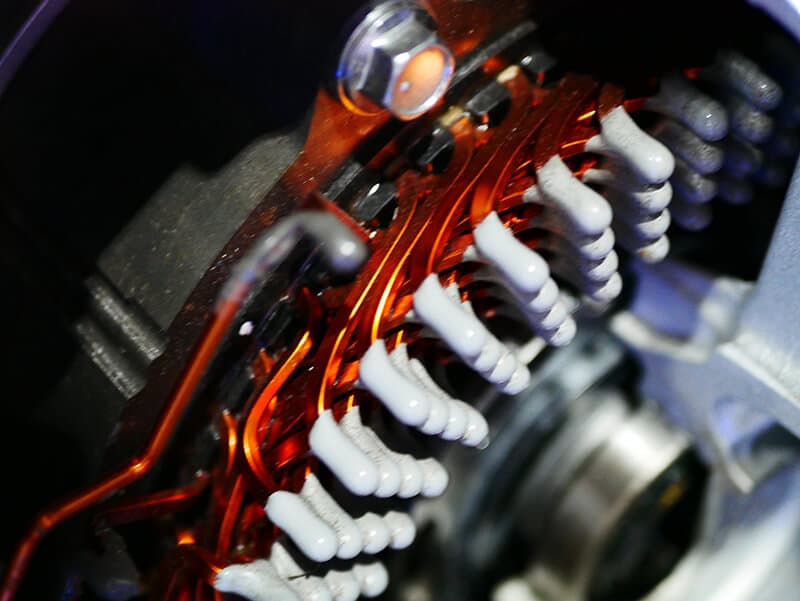

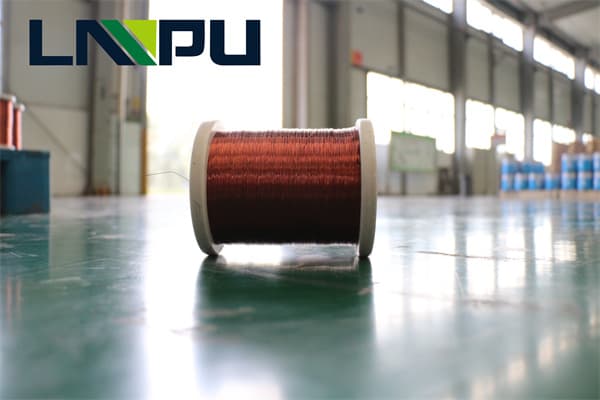

Copper lacquer wires are coated with respective lacquer solutions, and then cured by solvent volatilization and paint film.The earliest enamel wire is oily painted wire, made from tung oil.Its paint film is abrasion resistant, and cannot be used directly to make motor coils and windings, and the cotton yarn can be added to the layer.Later, polyethylene glycol formaldehyde lacquer wire came out, and its mechanical properties were greatly improved, which can be used directly for motor windings, which is called high-strength enameled wire.

Copper paint package wire production process principle

Copper lacquer wires are coated with respective lacquer solutions, and then cured by solvent volatilization and paint film.The earliest enamel wire is oily painted wire, made from tung oil.Its paint film is abrasion resistant, and cannot be used directly to make motor coils and windings, and the cotton yarn can be added to the layer.Later, polyethylene glycol formaldehyde lacquer wire came out, and its mechanical properties were greatly improved, which can be used directly for motor windings, which is called high-strength enameled wire.

With the development of weak electricity technology, there is a self-adhesive enameled wire, which can obtain a better coil without impregnating, baking.However, its mechanical strength is poor, and there can be only a micro-motor, and the small motor can be used.In addition, in order to avoid the trouble of removing the paint film, the direct weld paint package is developed, and the coating film can be easily welded in the high temperature sketch.